Badge custom making is a fine art, and Cloisonné (hard Enamel), soft Cloisonné (imitation hard enamel), and embossed soft enamel are three of the most common coloring processes. Each process has its own unique origin, technical characteristics, and suitable applications. Through a detailed explanation, ASNY Craft Factory will guide you from texture to fully understanding the differences between these processes, and how to accurately interpret them in both Chinese and English contexts.

Starting with Texture: The Secret to Flat vs. Embossed Surfaces

How can we simply distinguish between these three coloring processes? A quick judgment can be made based on touch:

- Smooth and Flat: Cloisonné (Hard Enamel), Soft Cloisonné (Imitation Hard Enamel),

- Embossed Texture: Embossed Soft Enamel.

Testing Method

Lightly slide your fingertip over the letters or design on the badge:

- If the letters feel smooth and level with the surface, it is likely a Cloisonné (hard Enamel), soft Cloisonné (imitation hard enamel)

- If the letters feel grooved or have an embossed texture, it is most likely an embossed soft enamel badge.

This simple and practical method is especially helpful for beginner badge enthusiasts or sales staff to quickly distinguish between these processes.

Misunderstandings in Translation Software and Client Communication: Avoiding Craft Definition Confusion

In the custom badge industry, translation software and communication with international clients often lead to misunderstandings about craft definitions, especially regarding the terms “Soft Enamel” and “Hard Enamel.” This confusion arises not only from the limitations of translation tools but also from the contrasting definitions in Chinese and English contexts.

Scientific Discrepancies Between Chinese and English Definitions: Why Do These Terms Conflict?

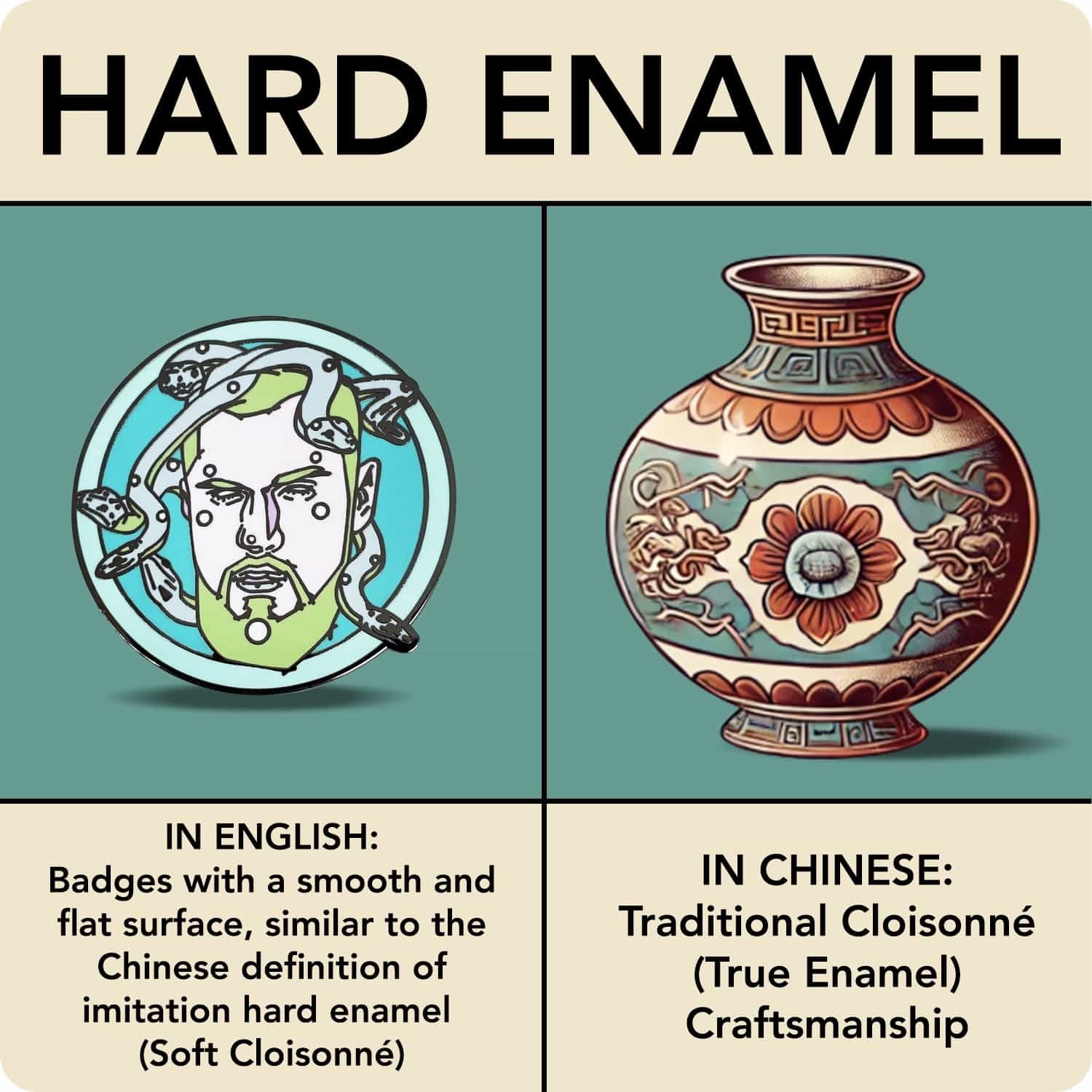

When browsing English badge knowledge websites, we often come across articles like “Difference Between Hard Enamel and Soft Enamel.” However, the descriptions in these articles can be in direct conflict with the understanding of these terms in Chinese contexts:

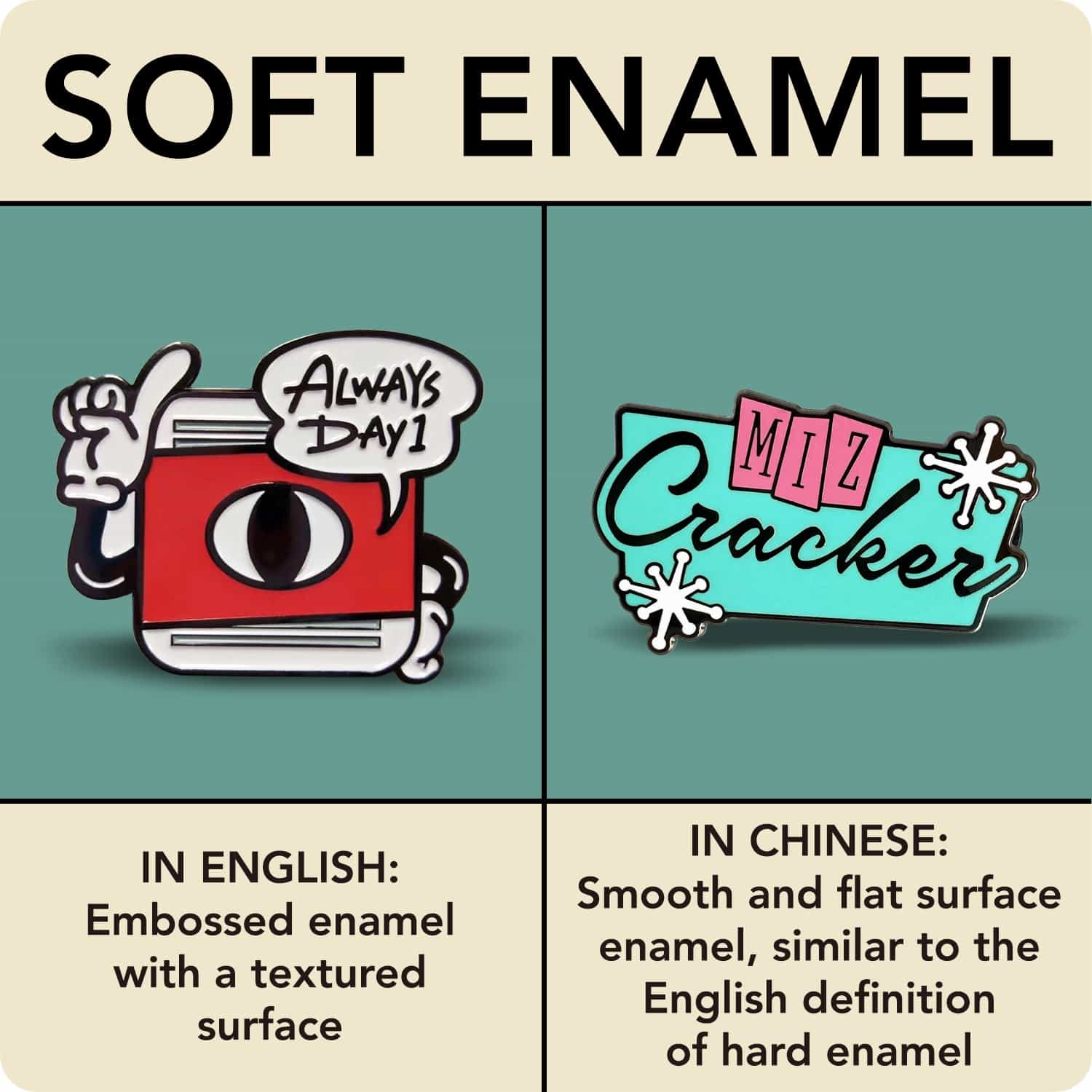

- In English, “Hard Enamel” refers to badges with a smooth, flat surface, which aligns with the Chinese definition of soft Cloisonné (imitation hard enamel).

- In English, “Soft Enamel” refers to badges with a textured, embossed surface, which corresponds to the Chinese process of embossed soft enamel.

This conflict can be confusing: why is “Soft Enamel” translated into Chinese as “软珐琅” (soft enamel, meaning smooth-surfaced badges), but in English knowledge websites, it is described as a process that results in a textured, embossed surface?

The Problem with Translation Software: Why Direct Translation Causes Conflict

When translation software directly translates “Soft Enamel” into Chinese, it often translates as “软珐琅.” However, this translation is misleading:

- In English, “Soft Enamel” refers to an embossed soft enamel process (with a textured surface).

- In Chinese, “软珐琅” refers to an imitation hard enamel process with a smooth, flat surface.

This direct translation often leads to confusion, as it may lead factories to believe that customers want a smooth-surfaced badge when in fact they are referring to a textured enamel process. For example:

- In Chinese, “软珐琅” suggests a smooth-surfaced enamel process. If translated directly to “Soft Enamel,” a factory might mistakenly think the customer requires a smooth badge.

- In English, “Soft Enamel” refers to a process with a textured surface (embossed soft enamel).

Such conflicts are particularly evident when international clients express their needs directly, potentially leading to production results that do not match the client’s expectations, thereby affecting the accuracy of order deliveries.

The Root Cause of the Conflict: Different Emphases in Chinese and English Craft Definitions

The conflict in craft definitions between Chinese and English primarily arises from the different emphases in the language:

- English Market: More focused on the product’s texture and visual effects. “Hard Enamel” emphasizes a smooth surface and durability, while “Soft Enamel” highlights the textured feel and visual contrast.

- Chinese Market: Traditionally, product attributes are described by the craft name. “硬珐琅” (hard enamel) refers to a complex high-temperature firing process (like Cloisonné), while “软珐琅” soft Cloisonné (imitation hard Enamel) refers to a modern, improved process with a smooth surface, emphasizing the production method and final texture.

Why Does the Chinese Market have difference meaning on “硬珐琅” (Hard Enamel) and “软珐琅” (Soft Enamel)?

The naming convention comes from China’s long-standing tradition of Cloisonné craftsmanship:

- Historical Background of Cloisonné: Cloisonné originated in the Ming Dynasty and is a traditional process involving metal wire forming cells, filling them with enamel powder, and repeatedly firing and polishing the product. Due to its complexity and high-end nature, it was once used to create royal items and national badges. For example, early Chinese military badges often used the Cloisonné technique.

- Modern Improvements and “Soft Cloisonné”: With technological advancements, this traditional technique gradually evolved into the modern “soft enamel” process, which retains the smooth surface characteristic but is more efficient and suited for mass production.

Thus, “硬珐琅” (hard enamel) and “软珐琅” (soft enamel) not only classify craft techniques but also preserve the cultural and historical continuity of China. This naming convention contrasts sharply with Western markets, which tend to focus more on texture and visual effects.

Factory Terminology Strategy: Ensuring Accurate Communication of Client Needs

To resolve the conflicts arising from translation and cultural differences, professional factories typically adopt the following strategies:

- Soft Cloisonné or Imitation Hard Enamel: Used to describe the smooth, flat surface process known as “软珐琅” (soft enamel) in Chinese.

- Embossed Soft Enamel: Clearly refers to the embossed enamel process (with a textured surface), eliminating the potential confusion caused by the direct translation of “Soft Enamel.”

By using these more specific terms, factories can ensure that client requirements are communicated clearly and accurately, reducing production discrepancies.

The Role of Embossed and Modifier Terms: Clarifying the Differences Between Enamel and Imitation Enamel Processes

To minimize misunderstandings in international communication, factories often use more precise terminology to describe different processes:

- Embossed Soft Enamel: By adding the term “Embossed,” it clearly indicates that the key feature of the Soft Enamel process is its textured surface, distinguishing it from the flat surfaces of “Soft Cloisonné” or “Imitation Hard Enamel.”

- This terminology not only eliminates potential confusion but also precisely conveys the characteristics of the embossed enamel process: after painting, the piece is baked at high temperatures to form a slightly raised metal edge above the enamel areas.

Additionally, modifiers for the “Hard Enamel” process are also important:

- Soft Cloisonné or Imitation Hard Enamel: Many badges referred to as “enamel badges” in modern times are imitation hard enamel badges.

- This distinction should be clarified. By adding “Soft” before “Cloisonné” or “Imitation” before “Hard,” factories can more accurately convey that these products are modern improvements, not traditional Cloisonné techniques. This not only avoids misunderstandings from clients from different cultural backgrounds but also reflects the factory’s professionalism and integrity.

Why Precise Communication is So Important

Direct translations by software and the differences in knowledge contexts between languages often cause misunderstandings in international collaborations. These misunderstandings can lead to production outcomes that do not meet client expectations, affecting both customer satisfaction and trust.

By clarifying terminology, specifying requirements, and introducing key modifiers (such as “Embossed” or “Imitation”), factories can effectively bridge linguistic and cultural gaps, enhancing the efficiency and accuracy of cross-cultural collaboration. This is a critical issue that every professional badge factory serving global clients should pay close attention to.

Detailed Analysis and Selection Guide for the Three Processes

In badge making, Cloisonné (hard enamel), soft Cloisonné (imitation hard enamel), and embossed soft enamel are the three most common processes. Each process has its unique origin, characteristics, and applicable scenarios. The following detailed comparison of materials, texture, production processes, appearance features, and application scenarios will help you select the most suitable production process for your needs.

Origins and Craft Analysis of the Three Processes

- Cloisonné (Hard Enamel): The Pinnacle of Traditional Craft

Cloisonné, also known as hard enamel, is an ancient and high-end craft with a rich history:

- Origin: Originating in China during the Ming Dynasty, it is regarded as a “treasure of golden and jade harmony.” It was initially used for royal items and national-level badges, such as military medals.

- Craft: This process uses metal wires to outline designs, which are then filled with enamel powder and fired at temperatures exceeding 800°C. After firing, the surface is polished multiple times to achieve a smooth and durable finish.

- Features: The final product has a strong gloss, vibrant colors, and high artistic and collectible value.

- Limitations: It is costly, time-consuming, and not environmentally friendly. As a result, it has gradually been replaced by imitation enamel.

- Soft Cloisonne (Imitation Hard Enamel): A Flexible Modern Alternative

Soft enamel is a modern alternative to hard enamel:

- Origin: Developed in the late 20th century to reduce costs and improve production efficiency.

- Craft: This process uses low-temperature filling of resin-based colors, which sit level with the metal edges. No high-temperature firing is required, allowing for more complex designs such as detailed text and multi-layered patterns.

- Features: Rich in detail and cost-effective, making it ideal for custom badges and commemorative items.

- Embossed Soft Enamel: The Best Choice for Efficiency and Mass Production

Embossed enamel focuses on production efficiency and visual impact:

- Origin: An innovation from the industrial production era, designed to meet the needs of corporate promotions and event commemorations.

- Craft: Special enamel paint is applied into a metal mold and baked at high temperatures, solidifying to form unique textured patterns.

- Features: The resulting product has vibrant colors and strong visual contrast, making it perfect for mass production, especially for event souvenirs and corporate promotional badges.

| Category | Hard Enamel (Cloisonné) | Soft (Imitation) Enamel (Soft Cloisonné; Imitation Hard Enamel) | Embossed Enamel (Embossed Soft Enamel) |

| Material | Enamel powder (glass material) | Resin or polymer | Special enamel paint |

| Texture | Smooth, level with metal | Smooth, level with metal | Textured, with raised areas |

| Production Process | High-temperature firing (>800°C), multiple polishing | Low-temperature filling and baking, retains metal texture | Painted and baked to solidify |

| Appearance Features | Full color, glossy finish, strong texture | Bright colors, clear layers | Rich colors, strong line effects |

| Applications | High-end souvenirs, art collections | Custom badges, keychains, souvenirs | Corporate promotions, mass-produced event badges or souvenirs |

| Cost | High | Medium | Low |

| Environmental Impact | Not eco-friendly, gradually decreasing use | More eco-friendly, cost-effective | Efficient, eco-friendly, suitable for mass production |

| Typical Products | Cloisonné, medals | Complex design badges | Event commemorative badges |

Summary: Choosing the Right Craft for Your Needs

- Art and Historical Legacy: If you value high-end craftsmanship and cultural heritage, Cloisonné (hard enamel) is the best choice.

- Flexibility and Cost-Effectiveness: For complex designs while controlling costs, soft Cloisonné (imitation hard enamel) offers distinct advantages.

- Efficiency and Affordability: For mass production or event promotion badges, embossed enamel is the top choice.

Through ASNY Craft Factory’s guide to these different badge coloring processes, we hope you have gained a deeper understanding of their origins and features. With this knowledge, you can choose the most suitable craft for your project, allowing your badges to not only convey meaning but also showcase exceptional craftsmanship and value.