Introduction

Metal badges hold a significant place in gifts, souvenirs, ornaments, and brand promotions due to their diverse production techniques and unique customization options. From die stamping, die casting, and etching to printing, along with coloring techniques like hard cloisonné (enamel) and soft enamel, these methods endow badges with rich forms of expression. However, it is the surface treatment processes that truly enhance the tactile feel, texture, and functionality of badges. These techniques not only bring additional visual impact but also elevate the badges' practicality and artistic value. This article provides an in-depth analysis of each technique’s principles, features, and applications, unveiling how these treatments shape high-quality badges.

1. Polishing: Imparting Smoothness and Luster to Metal

Principle

Polishing is a technique that smoothens and brightens metal surfaces through mechanical or manual operations. It uses abrasive materials (such as grinding wheels or polishing paste) to create friction with the metal surface, removing oxides, burrs, and minor irregularities to improve smoothness and shine. The process consists of rough polishing and fine polishing: rough polishing quickly removes coarse layers using larger abrasive grains, while fine polishing uses finer abrasives for intricate adjustments, achieving mirror or matte effects. The precision of equipment, pressure, and timing is critical to the final outcome.

Applications

- Standard Polishing: Enhances the basic smoothness of mass-produced badges such as employee ID badges and school commemorative badges, facilitating subsequent processes.

- Mirror Polishing: Achieves a bright, reflective surface, ideal for premium corporate badges and award ceremony badges, exuding luxury and refinement.

- Matte Polishing: Provides a soft, non-reflective finish, often used in modern designs like eco-themed or artistic badges.

2. EDM Treatment (Fine Sand Effect): Creating Delicate Matte Textures

Principle

EDM treatment employs electrical discharge machining to create fine textures on metal surfaces through micro-pulsed discharges between an electrode and the metal. This generates localized high temperatures, vaporizing trace amounts of material and forming subtle indentations. Conducted in an electrolyte or insulating medium, EDM ensures precise handling of intricate patterns and localized details, outperforming traditional mechanical techniques.

Applications

- Retro-Style Badges: Adds a sophisticated, historical feel to cultural badges.

- Architectural Badges: Enhances the dimensionality of architectural lines for vivid designs.

3. Sandblasting: Achieving Matte Effects on Large Surfaces

Principle

Sandblasting propels fine particles (such as quartz sand or glass beads) at high speed using compressed air onto the metal surface. The particles create uniform depressions upon impact, removing oxidation layers and impurities to produce a matte or frosted finish. The texture's granularity depends on the particle type and size. Sandblasting requires precise control over the angle, distance, and duration to ensure consistent and uniform results.

Applications

- Corporate Badges: The understated matte finish complements modern and minimalist logos.

- Sporting Event Badges: Combines sandblasting with electroplating for a professional, stylish look.

4. Glitter Treatment: Adding Sparkle and Glamour

Principle

Glitter treatment involves blending ultra-fine glitter particles (such as metallic powder or pearlescent powder) with transparent coatings, which are then evenly applied to the badge surface. The reflectivity of the glitter is determined by the size of its particles and the thickness of the coating, while the glossiness of the transparent layer further enhances its visual appeal. This process requires precise control to ensure uniform application and adhesion, maintaining its radiant finish over time. The glitter technique is highly versatile, allowing for full coverage or selective designs to suit various needs.

Applications

- Full-Coverage Glitter: Applied across the entire badge surface, this technique creates a consistent and dazzling effect, making it perfect for holiday themes and large-scale event badges.

- Christmas Badges: Red and green glitter adds a festive atmosphere.

- Anime-Themed Badges: Multicolor glitter emphasizes the whimsical and magical qualities of characters.

- Theme Park Souvenir Badges: Full glitter coverage grabs attention, adding fun and collectible appeal.

- Anniversary Badges: Gold or silver glitter conveys grandeur and solemnity for celebratory events.

- Selective Glitter Design: Glitter is strategically applied to key areas of the badge to emphasize focal points and create layered effects.

- Wedding Commemorative Badges: Glitter enhances names or wedding dates, adding a romantic, memorable touch.

- Brand Logo Badges: Glitter highlights logos, increasing brand visibility and appeal.

- Music Festival or Party Badges: Glitter accents on themed text or logos enhance the festive vibe and create strong visual impact.

5. Flow Sand: A Dynamic Visual Experience

Principle

Flow sand involves sealing colored sand particles or liquid within a transparent chamber. Using principles of gravity and fluid mechanics, the particles flow dynamically, creating a visually engaging effect. Transparent chambers, typically made of durable resin, ensure smooth movement and longevity. The choice of particle color, size, and shape determines the visual impact, while the chamber’s clarity enhances the dynamic appeal.

Applications

- Children’s Day Badges: Captures children’s attention with interactive designs.

- Tourist Souvenirs: Combines landmark elements with flowing effects for added collectible value.

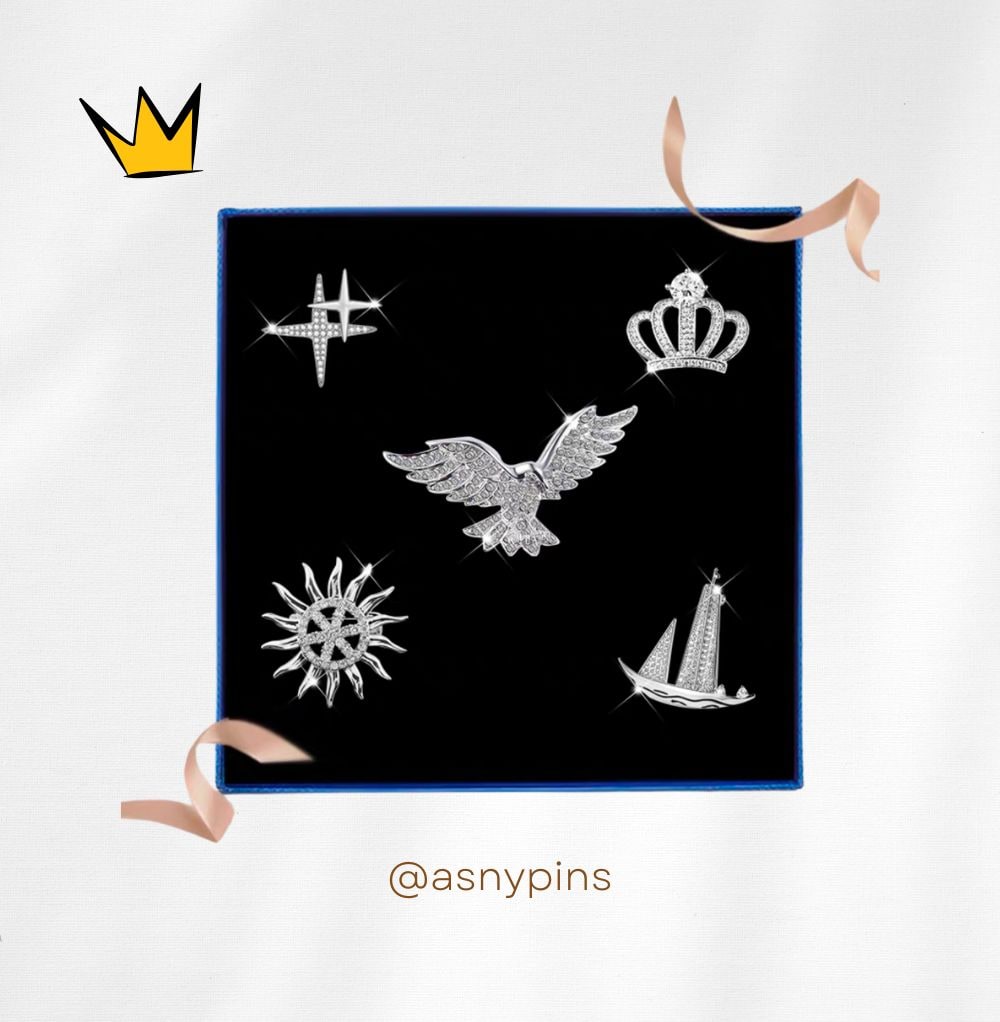

6. Rhinestone Setting: A Symbol of Luxury

Principle

Rhinestone setting involves creating openings on the metal surface and securing synthetic stones (such as zirconia or rhinestones) using prongs, adhesive, or other fixing methods. The cut angles, surface finish, and orientation of the stones directly affect the refraction and reflection of light, determining their brilliance. This technique demands secure fixation to withstand vibrations and wear over prolonged use while ensuring a tight integration between the stones and the metal base to maintain overall design cohesion and aesthetic appeal. Additionally, diamond setting is often combined with 3D badge designs and embossed details to enhance the overall visual depth.

Rhinestone setting can be categorized into two forms: full-diamond and partial-diamond designs. Full-diamond designs cover the entire badge surface, exuding ultimate luxury, while partial-diamond designs highlight specific details such as text, logos, or patterns, adding a finishing touch to the design. Both forms combine 3D modeling and intricate textures, enriching the badge's layers and artistic expression.

Applications

- Badges with Jewelry or Diamond Themes: Diamond setting naturally complements badges with jewelry or diamond-related themes. For instance, brand or gift badges adorned with synthetic stones not only enhance the luxurious feel of the badges but also align with the high-end image of jewelry brands. Full-diamond designs are especially suitable for luxury-related events or VIP-exclusive badges, using sparkling stones to emphasize prestige and exclusivity.

- Vintage Eastern European Badges: Diamond setting is widely used in many vintage-style Eastern European badges. These badges often feature 3D designs, intricate engraving details, and diamond accents, showcasing a strong sense of history and craftsmanship. For example, certain noble family crests or commemorative gift badges are embellished with synthetic stones, creating badges that are both vintage and opulent, with cultural significance and collectible value.

7. Epoxy (Resin Coating): The Perfect Combination of Protection and Decoration

Principle

Epoxy coating, also known as dome resin, involves evenly covering the badge surface with a layer of transparent or colored epoxy resin, forming a hardened protective layer upon curing. During the curing process, the resin starts in a highly fluid liquid state, ensuring it can spread evenly across the badge surface. As it begins to solidify, it transitions into a gel-like state, allowing it to fill uneven areas while still maintaining slight stickiness. Finally, the resin fully hardens into a solid state, creating a smooth, durable, and waterproof surface.

This technique not only enhances the badge’s durability but also improves its visual appeal and tactile quality. Transparent epoxy adds a high-clarity protective film that makes patterns more vivid and increases overall gloss. Colored epoxy, on the other hand, incorporates pigments into the resin, offering greater flexibility in design and more vibrant color effects.

Scope and Limitations

Epoxy coating is particularly suitable for baked enamel and printed badges but is generally not recommended for soft cloisonné badges for the following reasons:

- Embossed Soft Enamel Badges: These badges feature pronounced textures with clear separations between color areas. Epoxy fills in the recesses, creating a completely smooth surface while preserving the rich color layers and vivid effects of baked enamel. This treatment adds both visual appeal and a polished tactile feel, ideal for scenarios requiring high aesthetic standards.

- Printed Badges: With a flat surface, epoxy effectively protects the intricate patterns from wear and tear while adding gloss for an attractive finish.

- Soft Cloisonné (Imitation Hard Enamel) Badges: These badges have relatively smooth surfaces with subtle tactile lines separating color areas. While epoxy could provide additional protection, it diminishes the unique natural texture of soft cloisonné, making it an uncommon choice.

Applications

- Transparent Epoxy: Provides durable protection for sports badges and outdoor commemorative badges.

- Colored Epoxy: Enhances visual appeal in anime-themed badges or creative designs.

8. Luminous (Glow-in-the-Dark) Treatment: Unique Radiance in Darkness

Principle

Luminous (Glow-in-the-dark) treatment uses phosphorescent materials to achieve self-illuminating effects. By evenly applying glow-in-the-dark powder to the badge surface, these materials absorb light during the day or under bright conditions, storing energy in their molecular structure. In dark environments, the stored energy is gradually released as a soft, visible glow.

The particle size and uniform distribution of the glow-in-the-dark material directly affect the brightness and duration of the glow. Larger particles typically provide longer glow times, while smaller particles result in higher brightness. This eco-friendly, power-free technique is an efficient choice for many badge designs. Modern glow-in-the-dark technology also supports multiple colors (e.g., green, blue, yellow), expanding design possibilities and meeting diverse thematic and functional requirements.

Applications

- Night Event Badges:Adds playful decoration for music festivals, camping, and other nighttime activities.

- Safety Badges: Provides additional visibility and security for wearers in dark environments.

9. Other Innovative Techniques: Future Trends

- Pearlescent Effect: Creates soft, elegant luster suitable for feminine or artistic designs.

- Foil Stamping: Applies metallic foil for a prestigious finish, ideal for honorary badges.

- Hammered Texture: Adds artisanal, vintage appeal.

- Micro-Engraving: Achieves intricate patterns for high-precision designs.

Conclusion

From foundational techniques like stamping and casting to coloring methods such as baked enamel and soft cloisonné, metal badge manufacturing offers diverse possibilities. Surface treatments further enhance tactile quality, visual effects, and functionality. Techniques like polishing, EDM, and sandblasting define texture, while glitter, flow sand, diamond setting, and glow-in-the-dark effects bring creativity and utility.

ASNY Craft Factory specializes in combining diverse manufacturing methods with professional surface treatments to deliver high-quality, personalized badges for gifts and souvenirs. Whether for brand promotion, event commemoration, or aesthetic design, we look forward to collaborating with you to explore the limitless possibilities of badge design, turning each creation into a masterpiece of functionality and artistry.