Introduction: Exploring the Diversity of Flat and Three-Dimensional Badge Designs

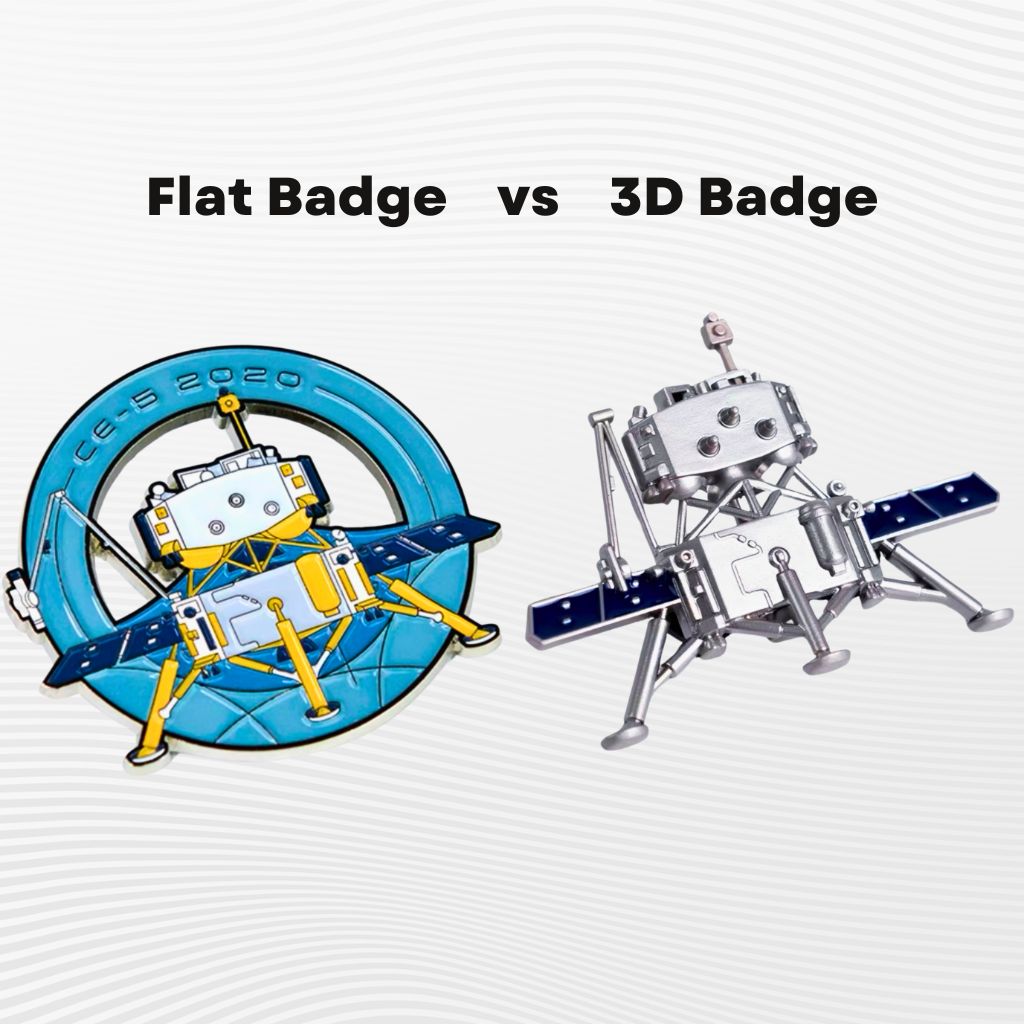

In the realm of custom badge design and manufacturing, traditional flat badges have long dominated the market. These badges, crafted with precision molds and high-accuracy coloring techniques, exhibit intricate details and complex textures. Typically, the production process begins with die-casting to establish the badge's overall shape and texture, followed by selecting the optimal viewing angle—such as front-facing, side-facing, or overlook view—to ensure the design meets aesthetic expectations. The next steps involve delineating regions with dividing lines and applying coloring techniques like embossed soft enamel or imitation hard enamel. For designs requiring high color fidelity, gradients, or a photographic effect, advanced methods such as lithographic printing or UV printing are employed. These techniques enable flat badges to deliver refined color gradations and intricate details, even within a limited surface area.

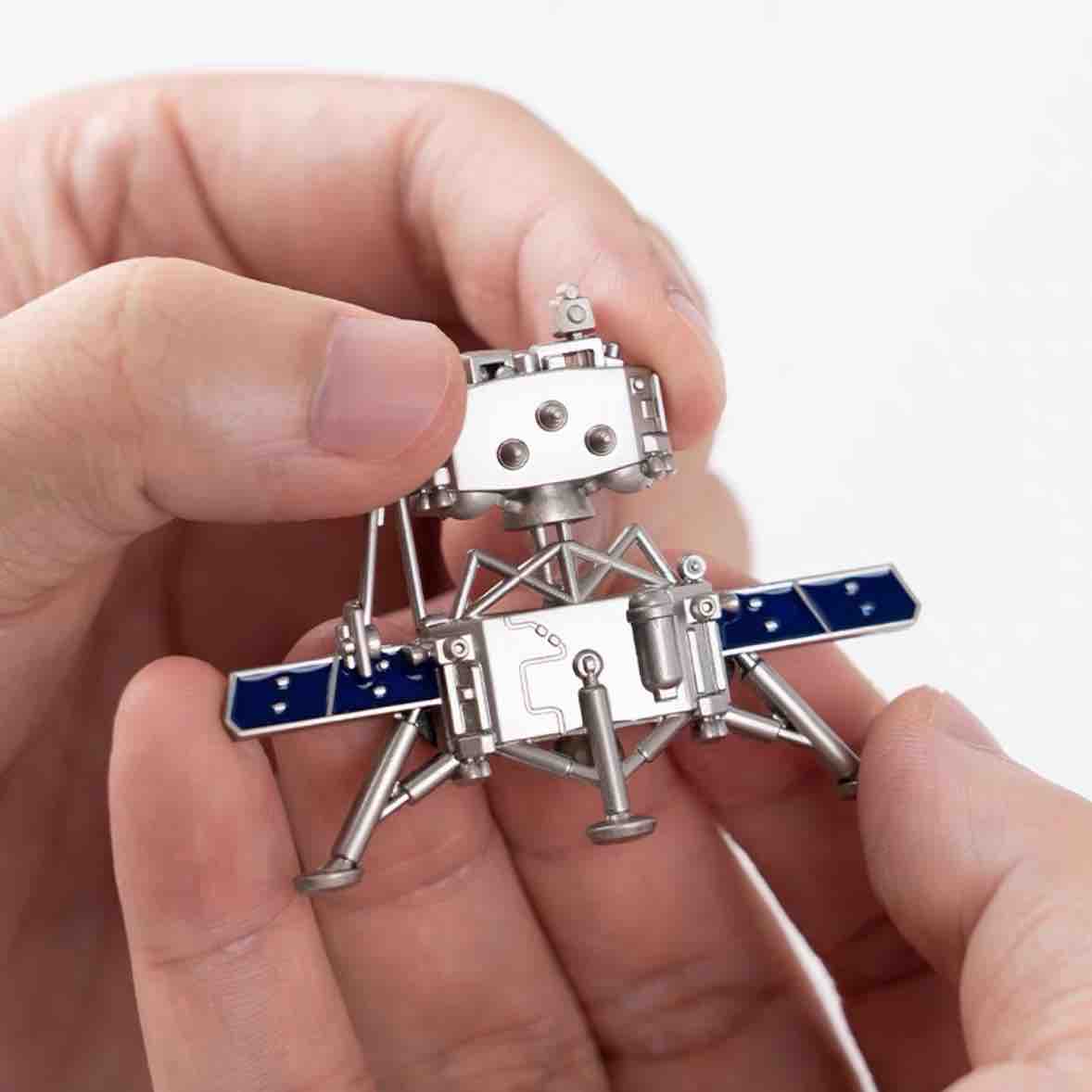

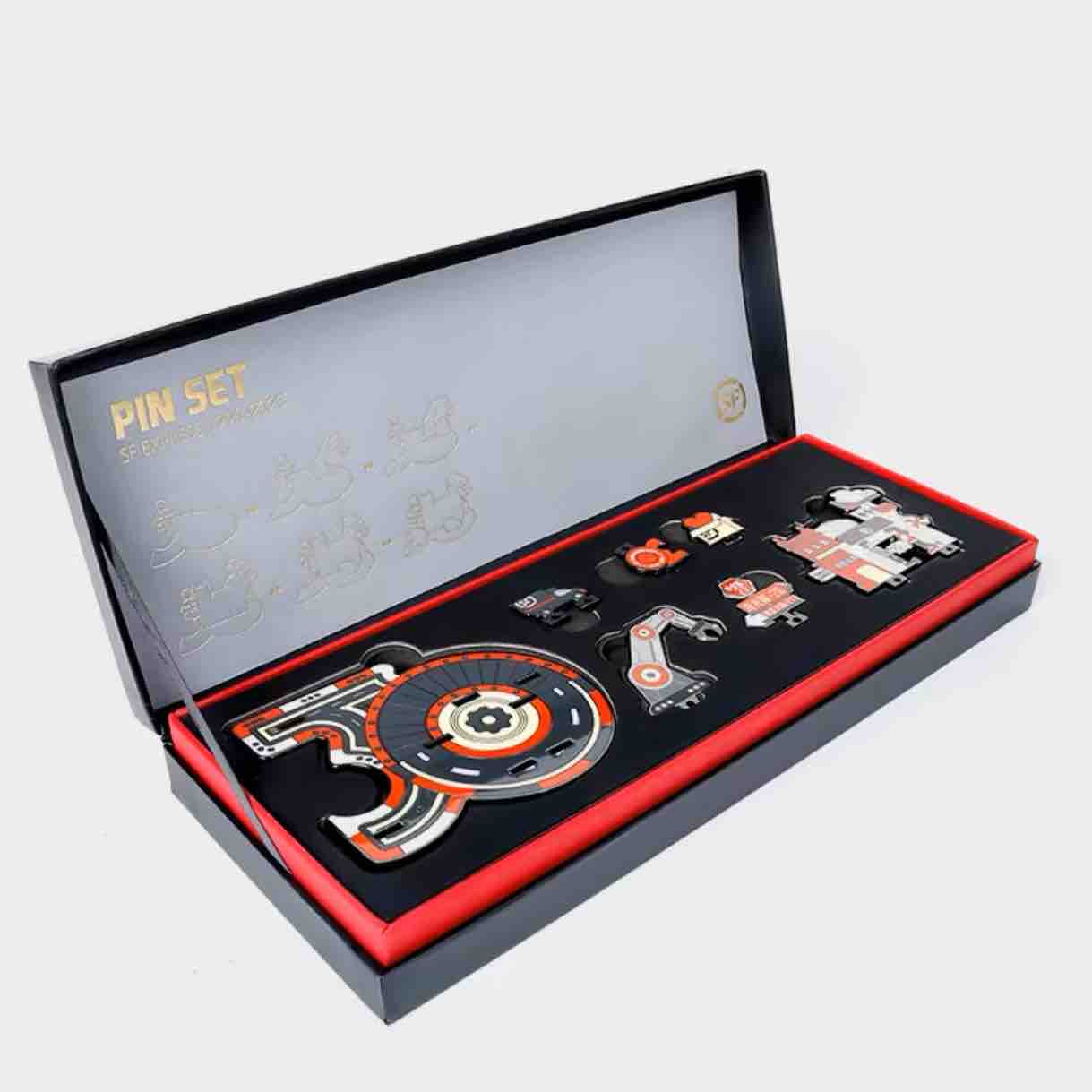

Take, for example, the motorcycle-themed badges displayed in the image. These badges use meticulous line engraving and precise coloring to authentically capture mechanical details and internal structures, showcasing exceptional craftsmanship. However, flat badges are inherently limited to two-dimensional representations, making it challenging to fully recreate the three-dimensional depth of real objects. This limitation has driven the emergence of 3D lapel pins, a revolutionary approach to badge design that opens new possibilities in craftsmanship through three-dimensional innovation.

Design Innovations and Concepts Behind 3D Lapel Pins and Brooches

- Breaking the Boundaries of Flat Design

3D badges employ sculptural designs to authentically replicate intricate forms. Models such as airplanes, motorcycles, and iconic architecture leverage high-precision modeling and engraving technologies, transcending the flat plane to deliver dynamic, detail-rich visual effects. These designs not only capture the overall contours of objects but also accentuate unique structures, such as the curvature of an aircraft’s wings, the intricate spokes of a motorcycle wheel, or the embossed patterns of architectural ornaments.

- Diverse Themes and Applications

- Classic Themes:

3D badges excel at recreating transportation models such as airplanes, tanks, and motorcycles, making them particularly suited for military themes, brand promotions, or collectible items. For instance, a motorcycle badge with detailed three-dimensional wheel designs highlights mechanical aesthetics, making the design inherently more appealing.

- Creative Themes:

Beyond real-world forms, 3D badges can incorporate creative elements like cartoon characters and anime figures. These dynamic designs bring characters to life with dimensional detailing, such as a character’s head or intricately textured clothing, adding energy and vibrancy to events or brand campaigns.

- Balancing Artistry and Functionality

3D badges are not merely artistic creations but also serve practical purposes. Whether as souvenirs, corporate gifts, or event merchandise, these badges convey emotions, culture, and brand values through their exquisite details. For instance, military-themed badges featuring airplane or tank models allow wearers to proudly showcase their identity or pay tribute to history.

Comprehensive Analysis of the 3D Badge Production Process: From Design to Manufacturing

- Design Phase: Precision 3D Modeling and Multi-Angle Preparations

- Design Preparation:

Although the final design of a 3D badge relies on 3D modeling software, the initial stages often involve drafting with tools like Photoshop (PS) or Illustrator (AI). Unlike traditional flat badges that only require front and back designs, 3D badges must consider details from multiple angles—front, side, and top views—even during the sketching phase. These multi-angle drafts serve as a comprehensive reference framework for 3D modelers, ensuring the design intent is accurately captured.

- Collaboration in Design:

The production of 3D badges is a complex process that demands tight collaboration across teams. From initial sketches to 3D modeling, mold-making, and final production, each stage requires the expertise of specialized professionals. As a leading expert in custom badge manufacturing, ASNY Craft Factory excels in creating 3D badges with a seamless blend of creativity and technical precision. From the imaginative ideas of designers to the technical expertise of modelers and the craftsmanship of mold makers, ASNY ensures that every 3D badge meets the highest standards, delivering truly unique and high-quality products for its clients.

- Mold Manufacturing: The Core Craft of 3D Badge Production

- Initial Design and Mold Layering:

After receiving the 3D modeling files, the production team performs a mold layering analysis based on the design. Due to the multi-angle and three-dimensional structure of 3D badges, molds must account for complex contours, curved surfaces, and intricate lines. For example, parts of an airplane model badge, such as the wings and fuselage, may be separated into multiple molds to facilitate assembly and detailing.

- Mold Engraving and Precision Processing:

The mold-making stage utilizes advanced CNC machining or Electrical Discharge Machining (EDM) for precise engraving, ensuring every angle and curve aligns with the design requirements. For intricate details, such as the recessed textures of motorcycle wheels or the window frames on architectural badges, adjustments to engraving depth and tool selection are carefully calibrated. The precision achieved during this stage determines the overall clarity and realism of the badge's final shape.

- Multi-Mold Integration and Trial Casting:

3D badge molds often include a primary mold for the main structure and auxiliary molds for individual components or enhanced textures. During the trial casting phase, the compatibility of different molds is tested to identify issues such as detail loss, warping, or size discrepancies. For highly complex designs, such as anime character badges, separate molds may be required for components like the head and body, which are later assembled.

- Mold Durability and Detail Optimization:

To withstand repeated high-pressure casting, 3D badge molds are typically made from high-strength materials like zinc alloy. To enhance durability and refine details, the molds undergo surface treatments such as nitriding or chrome plating, improving wear resistance and minimizing friction marks caused by metal flow. These optimizations ensure consistent quality during mass production.

- Solutions for Complex Designs:

Some intricate 3D badge details cannot be achieved with a single mold. For instance, the thin or delicate tail fin of an airplane badge may require an insert mold to cast the part separately before integrating it with the main badge. Additionally, for badges requiring custom logos or text plates, flat areas can be incorporated into the mold and later finished with hard enamel, embossed soft enamel, or UV printing for enhanced customization.

- Surface Finishing: Enhancing Texture and Detail Through Multi-Layer Techniques

- Surface Finishing and Coloring Techniques for 3D Badges:

3D badges often employ surface treatments like electroplating and polishing to enhance their metallic texture. Compared to flat badges, 3D badges have limited flexibility in coloring and usually feature electroplated finishes or 1-2 simple color schemes due to the complexity of their structures. However, selective coloring can be applied to flat sections of the badge. For instance, the body of an airplane badge can include a flat area for text or logos, allowing for additional customization with soft enamel or UV printing.

Scene Applications of 3D Lapel Pins and Brooches

- Military and Aviation Fields

- Military Commemoratives:

3D airplane model badges are widely used in military memorabilia and exhibitions, reflecting a sense of history and honor. These badges often commemorate significant events or aircraft used in key military operations, making them valuable artifacts for collectors and history enthusiasts.

- Aviation Culture:

At aviation exhibitions or space-related commemorations, there is a notable increase in demand for 3D badges featuring airplane or spacecraft models. These badges intricately reproduce the details of aircraft, such as wing contours and engine structures, offering a more realistic and tangible representation of aviation history.

- Automotive and Motorcycle Culture

- Motorcycle Models:

Motorcycle model badges are popular among enthusiasts and brand supporters, with intricate details such as wheel hubs, body proportions, and mechanical features being flawlessly represented through 3D design. These badges serve as collectible items and a means for motorcycle manufacturers to promote their brands.

- Automotive Brand Promotion:

By recreating classic car models in badge designs, automotive brands can better showcase their culture and values in events and product marketing. 3D badges can provide a unique and memorable way to engage fans and clients, celebrating iconic vehicles or achievements in the industry.

- Anime Characters and Personalized Collectibles

- Anime Characters:

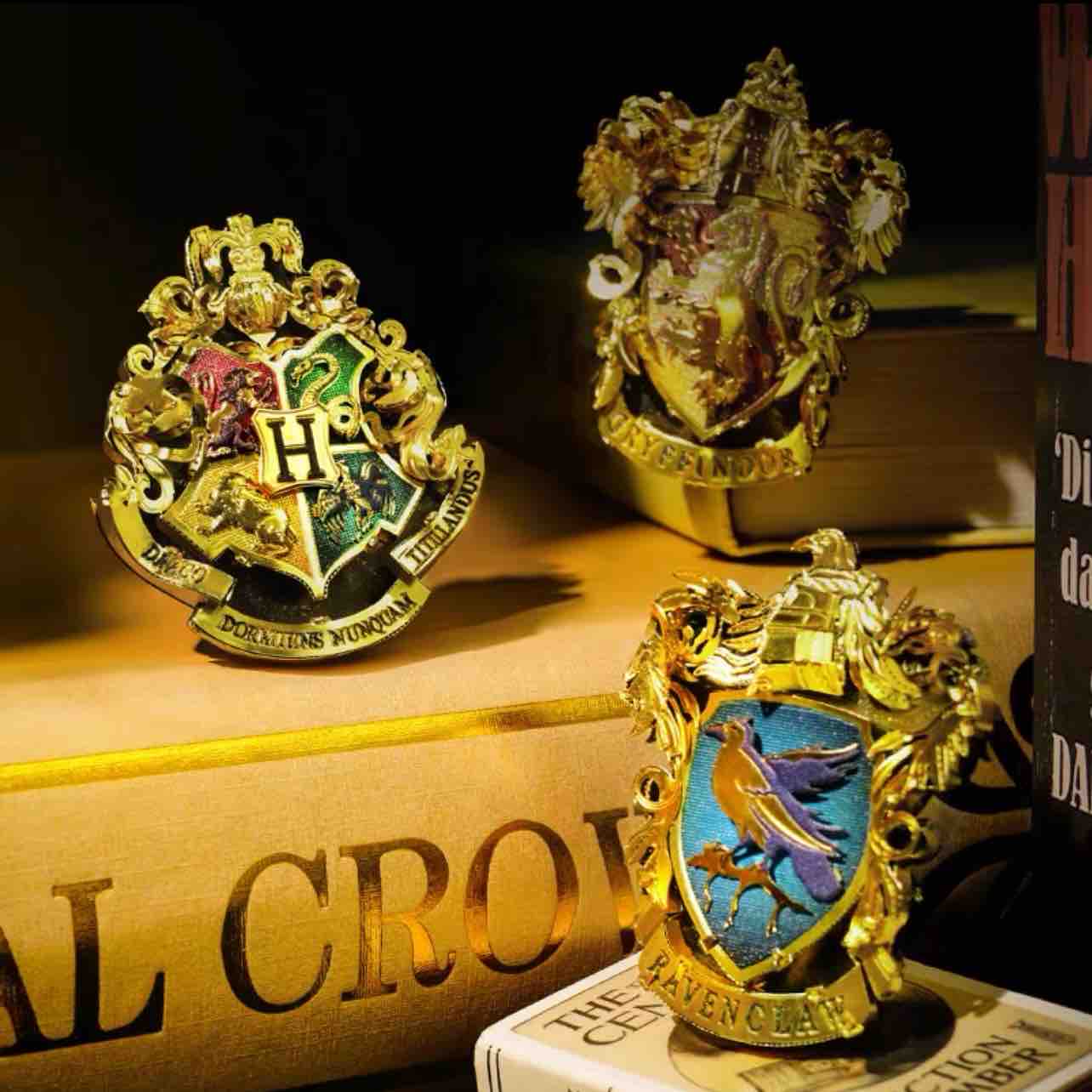

3D anime character badges capture a level of detail and depth that flat designs cannot, such as head shapes, costume textures, and facial expressions. These badges are particularly suited for fan groups and IP promotion, allowing for the creation of visually striking items that resonate deeply with fans.

- High-End Collectibles Market:

High-quality 3D badges, due to their rarity and exquisite craftsmanship, tend to have higher value in the collectibles market, especially in areas related to gaming and film IPs. These badges often become coveted items in the context of exclusive releases or limited editions tied to major franchises.

- Sports and Event Commemoratives

- Sports Events:

3D badges, such as those representing racing cars, combine vehicle models with event logos to become classic collectibles. These badges commemorate specific moments in sports history and are particularly popular among fans of racing or extreme sports.

- Cultural Events:

Badges designed with city landmarks or architectural models are often used as commemorative items for cultural events. These badges can capture the essence of a location or event, making them a popular souvenir for participants and visitors alike.

Current Status and Challenges of 3D Badges

Currently, 3D badges are not as mainstream as other 3D gifts and souvenirs, such as plaster sculptures, resin sculptures, or crystal sculptures. These larger 3D products are popular in home décor, commemorative collections, and personalized gifts markets due to their size and display nature. For example:

- Plaster Sculptures: Commonly found in art exhibits and high-end souvenirs, these sculptures are known for their intricate details and textured finishes.

- Resin Sculptures: Renowned for their low cost and high versatility, resin sculptures are often used in commercial promotions across various themes.

- Crystal Sculptures: Crystal sculptures, with their translucent appearance and premium positioning, are one of the top choices for corporate gifts and commemorative items.

In contrast, 3D badges are smaller in size and primarily intended to be worn, making them less likely to be used as display items compared to larger products. The practicality and symbolic significance of badges mean that their main function is decoration or identification, rather than being a decorative piece on display. This has led to a lower demand for 3D badges compared to other 3D products.

However, 3D badges can draw inspiration from these more popular 3D products and combine them with existing flat design technologies for innovation. For example, crystal sculptures are highly admired for their translucent visual effects, and similarly, 3D badges can try incorporating transparent resin materials in certain areas to give them a transparent feel, enhancing depth and visual three-dimensionality. Additionally, the technique of transparent enamel, commonly used in flat badges, can also be applied. Transparent enamel involves applying a layer of semi-transparent or transparent custom-colored paint to the metal surface, which is then cured at high temperatures. This process allows the color and texture of the metal base to show through. This technique is widely used in flat badges and effectively adds color layers while highlighting design details.

If the principles of transparent enamel are combined with 3D design, such as using transparent resin materials to replace certain metal areas in 3D badges or applying transparent enamel to flat parts of the badge (such as embedded nameplates or partial decorations), it can create a more layered design effect. For instance, a 3D airplane badge could use transparent resin to craft the windows of the aircraft, while applying transparent enamel to the nameplate on the body to reveal the electroplated base color of the brand logo. This combination of diverse techniques not only provides a unique visual presentation for 3D badges but also expands the possibilities for design, offering more directions for future creative development.

By integrating the transparent enamel techniques of flat badges with material innovations from other 3D products, 3D badges have the potential to achieve a more diversified design language in the future.

Conclusion: The Commercial Potential and Future Direction of 3D Badges

As consumer interest in traditional flat badges gradually declines, the rise of blind boxes has made 3D silicone or rubber figurines and dolls a popular choice in the souvenir and gift market, posing a significant challenge to the badge industry. To respond to this challenge, brands like Disney and Universal Studios have re-ignited consumer purchasing interest by combining badges with multiple flat molds and tiered base designs to create a sense of three-dimensionality and depth. Meanwhile, 3D badges take this a step further, offering true three-dimensional shapes and exquisite craftsmanship, giving badges higher artistic value and collectible significance, while gradually competing with the market for 3D silicone blind box figurines.

Despite this, 3D badges are not necessarily expected to fully replace flat badges, but rather to complement them. Flat badges, with their rich colors and intricate details, still maintain a strong appeal in certain markets. On the other hand, 3D badges broaden the application scenarios and target audience of badges through innovative designs and dimensional effects. In the future, 3D badges are expected to attract consumers who are enthusiastic about novel designs and personalized collections, offering businesses new market growth opportunities while injecting more vitality and possibilities into the badge industry.