Acrylic

High Transparency | Multifunctional Application | Suitable for Decorative and Practical Gifts

Acrylic gifts are highly valued in the gift manufacturing industry due to their high transparency and versatile applications. ASNY produces a variety of acrylic gifts, including keychains, fridge magnets, stationery, souvenirs, and promotional items. These are created using cutting, engraving, hot bending, and bonding techniques to meet customer demands for IP derivatives, brand peripherals, and retail products. The high transparency of acrylic material also makes it ideal for creating display items and decorative pieces. Laser engraving and UV printing can create detailed patterns and text on acrylic surfaces, enhancing the product's personalization and artistic appeal.

Additionally, acrylic gifts can include dynamic elements by incorporating liquids or other materials. The internal liquid flows when moved, adding unique visual effects and fun. By combining different structural designs and decorative elements, acrylic gifts can be made into Ferris wheels, shake stands, merry-go-rounds, and rocking stands. Three-dimensional functional acrylic gifts, such as display stands, are not only visually appealing but also practical, widely used for showcasing products and supporting equipment.

Silicone

Eco-friendly and Non-toxic | Durable and Anti-slip | Widely Used in IP Derivatives and Blind Box Products

Silicone material are highly popular in the gift custom and manufacture due to their eco-friendly, non-toxic, heat-resistant, cold-resistant, waterproof, moisture-proof, and anti-slip properties. ASNY utilizes various techniques such as molding, 3D surface drip molding, debossed color filling, embossed color filling, surface spraying, back printing, digital printing, and heat transfer printing to customize a wide range of silicone products, including flat silicone gifts, wristbands, figurine ornaments, wallets, card holders, and cosmetic bags. Silicone material, known for its high elasticity and tear strength, is also ideal for making anti-slip mats and functional accessories. Its self-adhesive smooth surface enhances anti-slip stability and adds decorative effects.

Silicone materials have been commonly used to produce custom wristbands for companies, organizations, exhibitions, events, and competitions. Nowadays, silicone is trending for creating 3D figurines, especially IP derivatives and blind boxes. With its moldability and high-precision forming capabilities, ASNY custom-produces 3D figurine ornaments with rich details and exquisite appearances, perfectly replicating brand designs. These can be paired with various packaging solutions for display or blind box purposes. ASNY continuously innovates in the silicone gift market, making silicone gifts an essential part of its product range.

Soft PVC

Low Cost and Eco-Friendly | Soft Touch | Colorful Designs

Soft PVC, known for its cost-effectiveness, environmental friendliness, and excellent softness, is the ideal choice for producing colorful and diverse designs. In our production, soft PVC is used to manufacture various promotional items, accessories, and everyday items such as keychains, fridge magnets, phone stands, and various tags. Its flexibility allows for the production of shapes and sizes ranging from simple to complex, and it can be quickly molded through the injection molding process. Soft PVC products can be added with a variety of colors according to needs, making the final products highly attractive in the market due to their vivid colors and soft touch. Furthermore, the eco-friendly attributes of soft PVC align with current market demands for sustainable products, making it a popular choice.

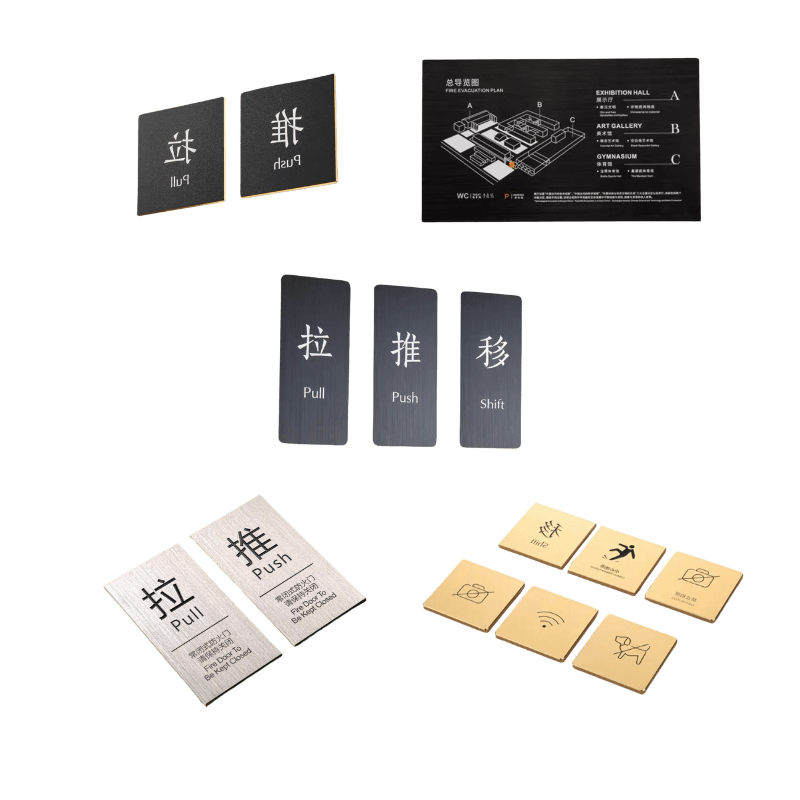

Aluminum

Lightweight and Strong | Easy to Process | Preferred for Modern Techniques

Aluminum material plays an essential role in modern industry due to its lightweight, high strength, and easy processing characteristics. In our factory, aluminum is used to manufacture various light metal products, such as signs, memorabilia, and promotional items. Through cutting, stamping, bending, and casting, aluminum material ensures precise realization of product designs and enhances production efficiency. The surface of aluminum can undergo anodization, not only enhancing its corrosion resistance but also providing a variety of color options to meet personalized customer needs. Especially in making pet tags, aluminum's advantages make it an ideal choice, as pet tags usually require being lightweight, durable, and available in various colors for owners to frequently change. These characteristics make aluminum highly suitable for applications that require frequent use or extensive handling.

Bronze

Historically Rich | Beautifully Durable | Elegant Metallic Luster

Bronze, a traditional and elegant alloy, is frequently used to manufacture various high-end decorative items and artworks due to its good corrosion resistance and unique color. In our factory, bronze is used to produce complex badges, exquisite medals, and other custom metal crafts. Its high strength and excellent fatigue resistance allow bronze products to withstand physical stress over time without deformation. Bronze's processing techniques include casting, forging, and etching, each step ensuring the finesse and durability of the final products. The finished bronze products, finely polished and appropriately chemically treated, exhibit a retro and noble luster, widely acclaimed in the market.

Red Copper

Excellent Conductivity | Warm Tone | Classic Charm

Red copper, known for its outstanding conductivity and unique reddish-brown luster, shows irreplaceable advantages in manufacturing high-end metal products. In our factory, red copper is widely used to produce items with a vintage style, such as high-end badges, exquisite bookmarks, and luggage tags. Red copper's high malleability allows it to realize complex pattern designs through various techniques like stamping, etching, and engraving. These products, after fine polishing and protective coating, not only retain the natural color of red copper but also enhance its corrosion resistance and enduring beauty. Red copper products, with their high-quality texture and classic aesthetics, hold a special place in the market.

Lead-Tin Alloy

Suitable for High-Temperature Casting | The Choice for Complex Designs

Lead-tin alloy is particularly suitable for casting intricate and complex small craft items in our product line, such as commemorative coins, decorative ornaments, as well as functional accessories like buttons and zippers. This alloy offers excellent fluidity and a low melting point, allowing it to accurately capture fine details and internal structures during the casting process, ensuring both aesthetic precision and functionality.

For buttons and zippers, the advantages of lead-tin alloy are especially evident. Its exceptional ductility and workability enable buttons to feature intricate engravings, vintage textures, or customized brand logos, while zipper pulls can be designed with unique shapes and a premium metallic finish. Additionally, finished products made from this alloy undergo meticulous polishing and custom plating treatments, enhancing their distinctive metallic luster while improving wear resistance and oxidation resistance. This makes them ideal for the fashion and accessories market, meeting demands for both durability and refined aesthetics.

The application of this material not only modernizes traditional casting techniques but also aligns with market demands for high-quality and diverse metal products.

Zinc Alloy

High-Precision Casting | Perfect Details | Multifunctional Applications

Zinc alloy holds a significant position in precision manufacturing due to its excellent casting characteristics and advanced surface smoothness. In our production process, zinc alloy is primarily used to create metal products requiring fine details and complex designs, such as decorative badges, exquisite medals, and functional keychains. This material not only has great fluidity that precisely fills the mold's details but also produces finished products with high surface quality and mechanical strength. Suitable for various post-treatments like polishing, electroplating, and painting, these processes enhance the aesthetic and durability of the products. Zinc alloy's characteristics make it an ideal choice for diverse market demands.

Iron

Economical and Strong | Ideal for Basic Metal Products

Due to its excellent physical strength and cost efficiency, iron is widely used in product manufacturing. At our factory, iron is utilized in creating a variety of basic metal products such as metal tags, keychains, and various decorative accessories. These products are formed through advanced stamping, welding, and bending techniques, showcasing the malleability and practicality of iron. With surface treatments like electroplating and coating, the corrosion resistance and aesthetic appeal of iron products are significantly enhanced, increasing their durability and attractiveness in a competitive market. Iron's properties make it an economical and reliable choice, suitable for mass production and extensive application.

Die Stamping

Copper, Iron, or Aluminum | Clear Embossing | Precise Pattern Outlines

Die stamping is a technique that uses gravity or pressure to shape and pattern metal sheets into specific forms. This process can be understood as "shape punching" and "pattern pressing." First, appropriate metal materials such as copper, iron, or aluminum are selected. Each material has unique properties: copper is soft, ideal for intricate patterns; iron is hard and economical, making it a mainstream choice; aluminum is lightweight and strong, suitable for special metal products.

In the "shape punching" step, a press or mold applies gravity or pressure to form the metal sheet into the desired shape. This step involves precise mold design and efficient pressure control to ensure accuracy and consistency in forming the metal sheet. The precision of the mold directly affects the quality of the final product, so careful attention to detail and tolerance control is essential in mold design and manufacturing.

Next is the "pattern pressing" step, where a pre-carved mold is used to press the designed pattern onto the metal surface. This step requires highly precise molds to ensure the pattern details are perfectly rendered. The pressure applied must be uniform and appropriate to avoid deformation or distortion of the pattern. This step results in a clear relief on the metal surface, creating the desired intricate patterns.

After stamping, the metal products can undergo polishing to smooth the surface or be electroplated with different finishes such as gold, silver, or nickel to enhance aesthetics, durability, and corrosion resistance. This technique is especially suitable for small metal souvenirs and gifts that require clear relief and defined contours, such as badges and keychains. However, for larger, more complex, or irregular shapes, stamping might not be ideal, and die casting may be necessary.

3-in-1 Color Changing Printing

Multi-Angle Color Changes | Triple Visual Experience

3-in-1 color changing printing is a more advanced dynamic printing technology that allows patterns or colors to show different visual effects at three different viewing angles. This technology uses a special print film that changes the visual state of the pattern into three distinctly different appearances, such as three different colors or patterns, depending on the viewer's position. This multi-angle change adds a unique interactive element to the product, making it visually appealing under different lighting and viewing conditions. 3-in-1 color changing printing is particularly suitable for high-end market promotions, art decorations, or technology displays, offering a rich and captivating visual experience.

2-in-1 Color Changing Printing

Dynamic Visual Effects | Dual-Angle Image Changes

2-in-1 color changing printing is achieved by adding a special color-changing print film on a metal base made through processes such as die stamping, die casting, or photo etching. The base can be designed with edges to wrap around the print film for additional protection and aesthetics, or without edges for a more natural image transition. The print film can display different images or color changes at different viewing angles, providing a unique visual experience to the observer. For example, a design could feature a character image that shows different postures at two different angles, or a logo that displays two different colors as the viewing angle changes, or transitions between day and night. This printing technology is particularly suitable for applications requiring multifunctional display and high interactivity, such as advertising displays, decorations, or personalized merchandise.

UV Printing

Instant Curing | Vibrant Colors | Suitable for Detailed Patterns

UV printing technology is an advanced method that utilizes ultraviolet light to quickly cure ink on product surfaces. This technique is especially suited for applications requiring rapid production and vividly colored patterns. UV printing can precisely replicate high-resolution images on various materials, ensuring clarity and lasting color fidelity. Commonly used in advertising and signage manufacturing, this method excels in multicolor printing where precise pattern alignment is critical. Additionally, the quick curing of UV inks reduces color bleed and mixing between materials, resulting in superior image quality and color contrast. This makes UV printing an ideal choice for high-quality printing needs.

Silk Screen Printing

Mesh Technique | Multicolor Registration | Clear Patterns

Silk screen printing is the ideal choice for creating multilayered, multicolored patterns. It is suited for designs that are finely detailed and richly colored, able to display various colors clearly without metal line separations. This technique directly prints ink onto the product surface through a mesh screen, particularly suitable for applications requiring clearly defined patterns and vivid colors. Screen printing can handle various materials and, by adding a layer of protective synthetic resin (AP), effectively prevents pattern fading and wear, ensuring the colors and patterns remain vibrant and intact over time.

Offset Printing

Copper, Stainless Steel, or Aluminum | Gradient Color Effects | High Precision Graphics

Offset printing is specifically used for designs requiring precise lines and rich layering. If your design resembles an oil painting or photograph seeking smooth transitions of all colors, lithography is the ideal choice. This technique achieves high-quality image reproduction by evenly printing ink on metal surfaces such as copper, stainless steel, or aluminum. Additionally, offset printed can create precise and deep visual effects on metal materials, enhanced by a layer of synthetic resin (AP) to boost image durability and ensure long-term protection and color retention.

Laser Cutting

High Precision Cutting | Suitable for Various Materials | Fine Outlines

Laser cutting is an advanced manufacturing technology that uses high-energy lasers to precisely cut materials of various harnesses, including metals, plastics, and composites. This method generates intense heat to quickly melt the material, forming fine cutting lines. Laser cutting is particularly suited for creating complex patterns and detailed contours, meeting the needs for high precision and smooth edges. Compared to traditional mechanical cutting, laser cutting offers faster speeds and higher efficiency, minimizing material waste by accurately controlling the cutting path. Additionally, the laser cutting process does not require physical contact with the material, reducing the risk of wear and deformation, thus enhancing the overall quality and appearance of the product. These features make laser cutting an ideal choice to produce metal ornaments, jewelry, signage, and souvenirs, especially suitable for manufacturing designs with complex appearances and precision components.

Lead-Tin Alloy

High-Temperature Tolerance | Suitable for Complex Designs

Lead-tin alloy is a material that easily melts at high temperatures and can precisely fill molds, very suitable for manufacturing products with complex shapes or unique designs. The fluidity of lead-tin alloy allows it to form fine details and smooth surfaces in molds. Its high-temperature tolerance also ensures stability during the casting process and the structural integrity of the finished products. Completed products can be enhanced in appearance through subsequent treatments such as electroplating or painting.

Photo Etching

Bronze Material | Wide and Clear Detail Outlines | Subtle Depth in Patterns

Under the process of photo etching, the outline of a product is transferred from a photographic film to a metal surface, typically bronze. The design is then etched onto the metal using an acidic solution, a step that requires careful handling of all acidic agents and mixtures to ensure safety and effectiveness. The recessed areas inside the metal are colored according to design specifications, and each color is cured in an oven until fully applied. After these steps, individual product shapes are cut from the entire metal sheet and further processed with electroplating to enhance durability and aesthetics. Finally, the product surface can be optionally coated with a protective synthetic resin (known as an AP layer) to improve weather resistance and prevent fading.

Die Casting

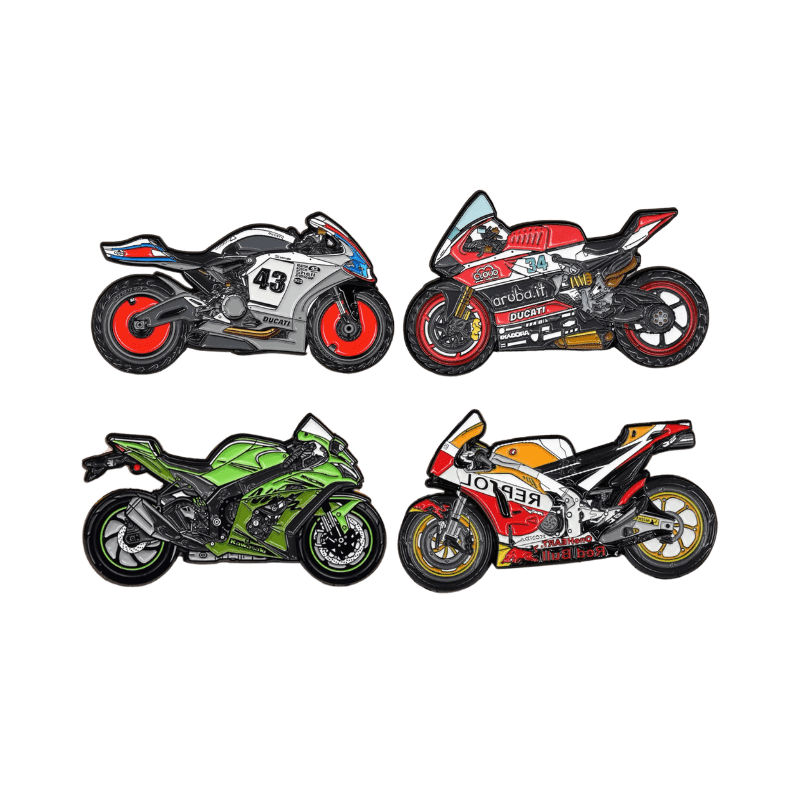

Zinc Alloy | Suitable for 3D Effects, Complex Designs, and Large

Die casting is an advanced metalworking technology widely used for manufacturing complex designs and large products. This process primarily uses zinc alloy, which, when melted at high temperatures, is injected into pre-made molds and solidifies into the desired shape upon cooling. The entire process includes several critical steps to ensure product quality and precision.

Firstly, the zinc alloy is melted at high temperatures, offering excellent fluidity and strength to evenly fill all parts of the mold, forming intricate and complex structures. The molten zinc alloy is then injected into the mold using an injection mechanism. The mold, typically made of high-strength steel, withstands high temperatures and pressures, and its interior is pre-engraved with the product's design shape to ensure the final product's dimensional accuracy and surface quality. The cooling phase is crucial in the die casting process. The molten zinc alloy in the mold gradually solidifies during cooling, forming the desired product shape. Cooling speed must be strictly controlled to prevent internal stress and deformation of the material, ensuring the product's mechanical properties and dimensional stability. The finished semi-products then proceed to coloring or surface treatment stages.

Die casting is suitable for high-precision 3D designs and the manufacturing of irregular shapes. Its advantage lies in the ability to easily create complex double-sided patterns and internal hollow structures, meeting diverse design requirements. This process is particularly suitable for producing dynamic or movable parts, such as combination badges and functional badges, and can provide reserved positions for adding LED lights, sliders, rotating discs, and rolling parts.

Essential Oil

Color Stability Enhancer | Balances Environmental and Health Concerns

In the surface treatment process of metal products, we typically add a suitable amount of essential oils to enhance the color stability of electroplating, paint, or ink. Essential oils not only form a protective layer to prevent color fading but also protect against wear. The use of this additive helps maintain the aesthetic and integrity of the metal surface, especially when exposed to harsh environments over long periods. While we focus on performance in our formulations, we also ensure that the ingredients chosen consider environmental impacts as much as possible, thereby balancing practicality with environmental responsibility. This approach not only enhances the practical value of the product but also meets the growing market demand for environmentally friendly materials.

Color Paste

Color Enhancer for Specific Applications | Edge Use

Although color paste is no longer a mainstream choice in modern metal products and its use is declining due to its complex application process and the availability of more diverse alternatives, it still plays a role in certain crafts where vibrant or strong coverage is needed on small areas. It can provide richer color performance and depth in details, especially in traditional handicrafts or restoration work, effectively supplementing or enhancing the original colors.

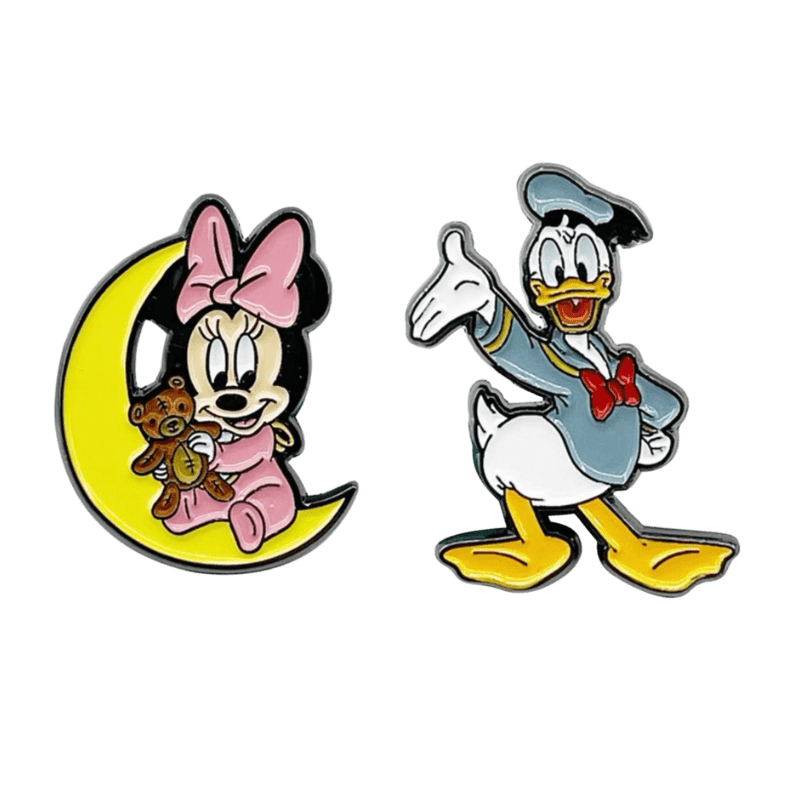

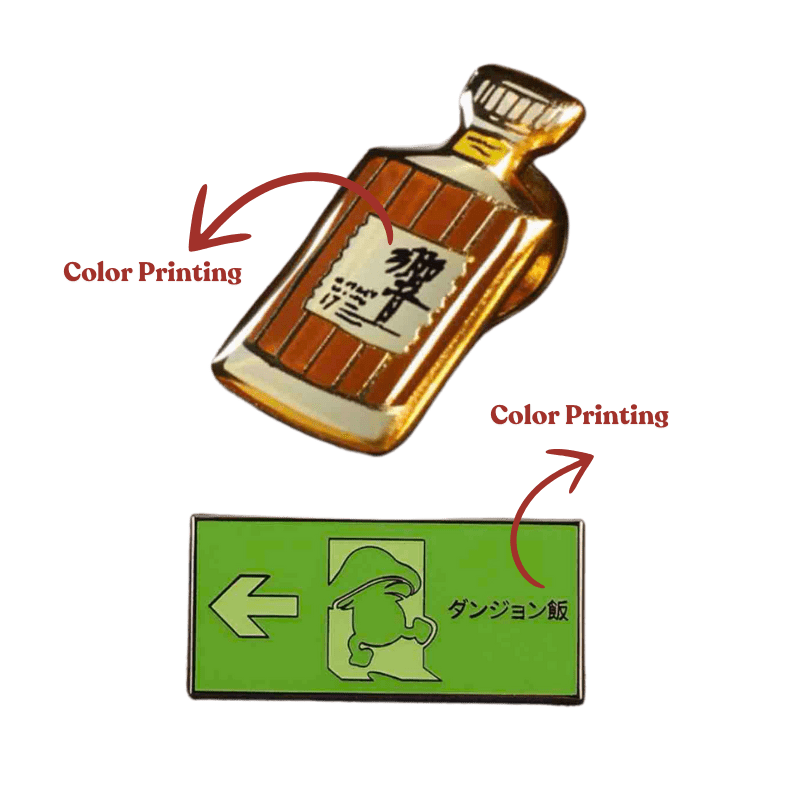

Color Printing

Precise Custom Area Coloring | Complements Main Coloring Techniques

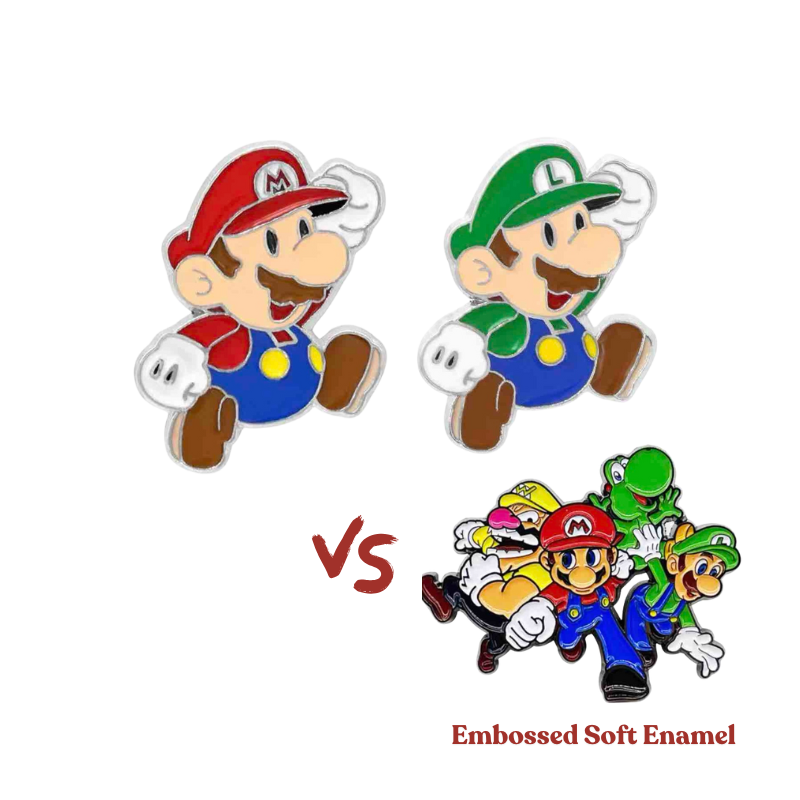

(Partial) Color Printing, as described in the “Processes” category, includes offset printing, screen printing, and UV printing. It is typically used in addition to primary coloring techniques such as embossed soft enamel or imitation hard enamel to achieve precise coloration in specific areas of a product. In metal products such as badges, these techniques are often applied to create gradient effects or accurately reproduce brand elements and logos in their standard colors—something that embossed soft enamel and imitation hard enamel cannot achieve. By using partial color printing, complex color transitions can be realized, and brand logos can be precisely replicated. This ensures that souvenirs and gifts closely replicate the visual appeal of the original brand products, maintaining brand consistency and creative expression.

Imitation Hard Enamel (Soft Cloisonne)

Fine Craftsmanship | Harmonious Colors | Even Appearance

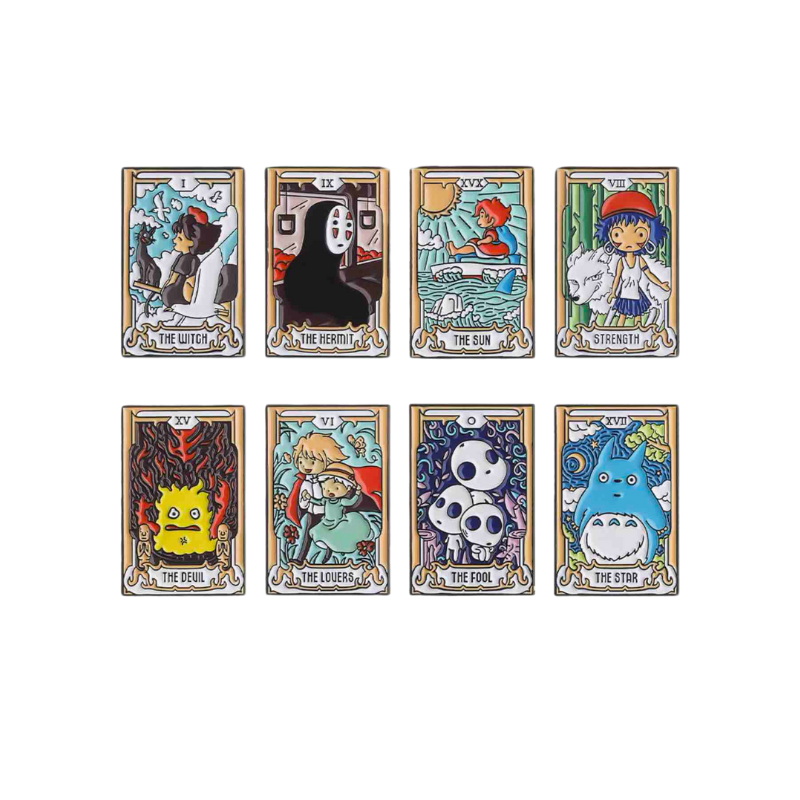

Imitation hard enamel, also known as soft cloisonne, is characterized using cost-effective resins or polymers as fill materials, with copper or zinc alloy serving as the primary base materials. High-precision molds are used to accurately cut out designs and borders. Metal lines not only define the shape but also separate different color areas. In terms of color processing, pigments mixed with hardeners are injected within these metal boundaries through automatic coloring machine and are cured in high-temperature ovens to harden the pigments and make them flush with the metal base, creating a seamless and refined surface. Imitation hard enamel is renowned for its vivid colors and clear boundaries, making the products visually stunning and tactilely exquisite. This technique is widely used in the creation of badges, medals, and memorabilia with intricate patterns and vibrant colors, perfectly meeting modern aesthetic and practical demands.

Hard Enamel (Cloisonne)

Traditional Craftsmanship | Rich Colors | Strong Durability

Hard Enamel (cloisonne) technique is an ancient handcraft that merges the aesthetics of metal and ceramics. It utilizes red copper as the base material. Precise molds are crafted based on the design patterns, which are then used to cut out the product's framework and intricate lines. High-quality enamel materials, such as cloisonné, are manually filled within the metal lines. The pieces are fired at temperatures exceeding 800 degrees Celsius, a process that not only solidifies the pigments but also ensures the colors do not bleed or fade. After completion, each enamel piece undergoes rigorous polishing and plating to enhance its durability and give it a variety of metallic sheens. This results in products that are not only vibrant in color but also smooth in surface, offering high durability and significant collectible value, making them highly sought after by collectors and art enthusiasts.

Transparent Embossed Soft Enamel

See-Through Beauty | Layered Decorative Effects

Transparent embossed soft enamel is a sophisticated surface coloring technology that applies a layer of customizable color, ranging from semi-transparent to transparent paint, on metal products, followed by high-temperature baking to cure the paint fully. This process enables transparent effects on metal items without a base, allowing underlying objects to be visible. On products with a base, transparent embossed soft enamel reveals the electroplated colors or the intricate designs of the base beneath. For instance, consider a badge where the central design like a character or logo is treated with standard embossed soft enamel while the surrounding areas use transparent embossed soft enamel, creating a visual hollow-out effect. This design not only enhances the visual depth of the product but also highlights the details of the central pattern, offering protection while maintaining decorative beauty. This technique is particularly suitable for color-rich badges, keychains, and other decorative metal crafts that need to showcase intricate themes.

Flat Embossed Soft Enamel

Smooth Surface | Uniform Coverage | Easy to Clean

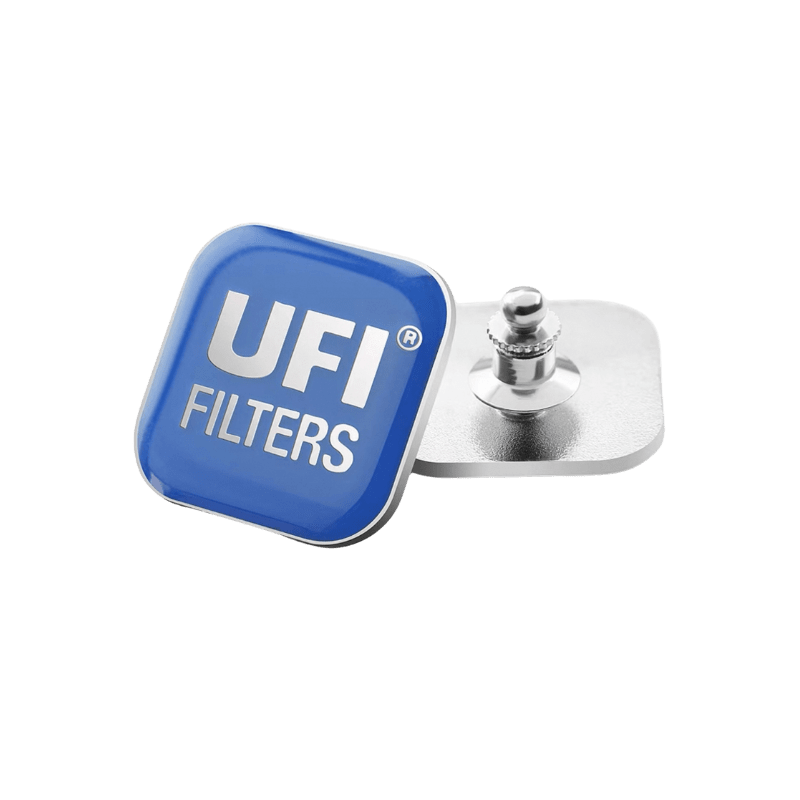

Flat embossed soft enamel process is particularly suitable for metal products requiring a smooth surface with reduced relief. After metals like copper, iron, or zinc alloy are pressed or injection molded, advanced coating technology applies paint evenly across the metal surface. The highly automated production line ensures that the paint application is both precise and efficient. The paint cures after high-temperature baking, forming a smooth and hardened outer layer that enhances the product's wear resistance and anti-corrosion capabilities, as well as making the surface easy to clean and maintain. This technique meets high standards of aesthetic and functional quality, widely applied in environments requiring frequent cleaning or uniform appearance.

Standard Embossed Soft Enamel

High-Temperature Baking | Lasting Gloss | Precise Coloring

Standard embossed soft enamel is a widely used color application process for metal surfaces. This technique involves selecting metals such as bronze, copper, iron, or zinc alloy and precisely stamping or injection molding them into shape. Semi-finished products are polished and electroplated to exhibit various metallic lusters. Initially, pigments were manually injected during the coloring phase, but the process has evolved with modern technology into a fully automated coloring system, ensuring uniform and precise color application. After mold scanning, machines automatically color the products, which are then baked at 160 degrees Celsius, curing the pigment layer to ensure strong adhesion and durability. Standard embossed soft enamel provides lasting vibrant colors and sharp line definition, making it extensively used in creating various badges and signage.

No Epoxy/Poly (AP)

Natural Texture | Original Elegance

Choosing no epoxy poly (AP) coating means opting not to apply any additional protective layers to metal products, preserving the metal's original state and natural luster. This treatment is suitable for products that do not require extra protection or need to showcase the metal's inherent texture and color. Products without AP coating better display the metal's natural beauty, suitable for applications that require a high degree of authenticity or traditional craftsmanship effects, such as some artworks and handcrafted metal ornaments.

Thick Epoxy/Poly (AP)

Enhanced Durability | Resistant to Extreme Conditions

Thick epoxy poly (AP) coating uses a thicker protective layer than standard AP, particularly suitable for metal products used in harsh environments. This thicker coating effectively resists severe scratches, wear, and chemical corrosion, greatly extending the product's lifespan. Thick AP is especially recommended for accessories of outdoor clothing, leather goods, backpack, and any metal parts that may face extreme conditions.

Thin Epoxy/Poly (AP)

Light and Transparent | Detailed Protection

Thin epoxy poly (AP) coating uses a thinner protective layer, designed to preserve the metal's original texture and details. This thin-layer coating technology is suitable for products that need detailed protection without altering the appearance. Although thin, the AP layer is sufficient to resist minor wear from everyday use, ideal for fine decorative items or high-end jewelry, especially those requiring the display of delicate metal craftsmanship.

Standard Epoxy/Poly (AP)

Balanced Protection | Economical and Practical

Standard epoxy poly (AP) coating offers a basic but effective protective layer suitable for most conventional applications. This standard thickness AP coating protects the metal surface from everyday wear and minor scratches, also enhancing its oxidation resistance. Standard AP is a cost-effective option, commonly used in the commercial and industrial sectors for metal products that require lasting durability but are constrained by budget.

Epoxy/Poly (AP)

Comprehensive Protection | Lasting Gloss

Poly (AP) coating is a coating technology that applies a special protective layer on the metal surface, enhancing the product's wear and corrosion resistance. This treatment improves the product's scratch resistance and maintains its long-term gloss. AP coating is not only aesthetically pleasing but also effectively prevents metal oxidation, extending the product's lifespan. Suitable for various metal products, including medals, badges, and decorative metal accessories, it is a widely used surface treatment technology. Products produced using printing processes often pair with AP coating to protect their ink-printed photos or designs.

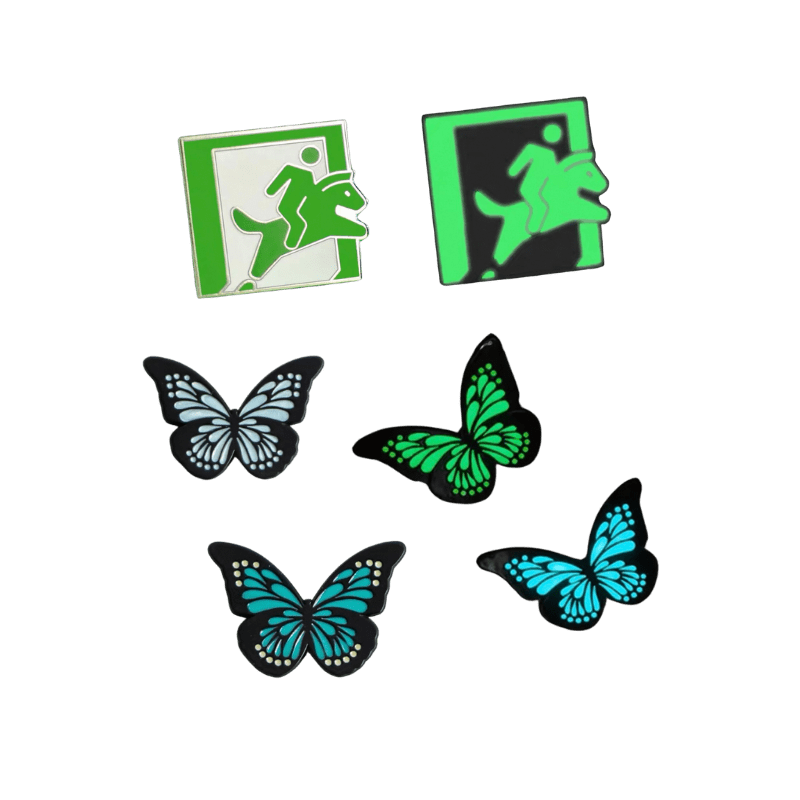

Luminous

Comprehensive Protection | Lasting Gloss

Luminous (glow-in-the-dark) technology integrates special luminescent materials into metal products, enabling them to emit light continuously in dark environments. These materials absorb light energy in daylight or well-lit settings and automatically glow in the dark or in low-light conditions. This technology is particularly suitable for enhancing the nighttime visibility and appeal of decorative items like lapel pins. The addition of luminous materials not only improves the product's utility in darkness, serving as a safety indicator during nighttime activities but also adds a mysterious and unique aesthetic, making the product more attractive in the collectibles and gift markets.

Rhinestone/With Diamond

Exquisite Luxury | Customized Decoration

The rhinestone technique is an advanced decorative process that enhances the luxury and visual depth of metal products by precisely embedding clear or colorful rhinestones. Its essence lies in the meticulous control of color combinations, arrangement density, and placement, while skillfully utilizing light and shadow effects to create a dazzling visual impact. This technique is widely applied to wearable accessories, such as brooches or medals.

The setting methods are highly versatile: single or a few high-luster rhinestones can be used to emphasize visual focal points, or a uniform row of rhinestones can be arranged around the product’s edges to enhance depth and three-dimensional appeal. ASNY excels in high-precision diamond setting, achieving an accuracy of up to 0.1mm. Each rhinestone is arranged uniformly and secured firmly, ensuring durability while maximizing light refraction. With strict control over rhinestone transparency, color purity, and placement angles, every piece shines brilliantly under varying lighting conditions.

Liquid Flow Sand

Flowing Visual Aesthetics | Enhanced Dynamic Effects

The glitter finish process involves uniformly dispersing one or several layers of glitter particles on the metal surface, providing the product with unique visual allure. This decorative technique can employ single-color glitter for a simple yet sophisticated shine or a mixture of multiple colors to create a rich, colorful effect. The density of the glitter particles can be adjusted—from finely sprinkled to create a subtle shimmer to broadly scattered for a more striking luminous effect. Additionally, there is an option to apply a transparent polyresin coating (AP) over the glitter layer. The poly coating not only smoothens the surface touch but also enhances the brightness of the glitter, making the reflections more prominent. Without the poly coating, the original matte texture of the glitter is preserved. Glitter is suitable for badges, keychains, fridge magnets, and trophies, frequently used in anime, cartoon, or sci-fi themed products.

Glitter

Multicolored Sparkle Effects | Enhanced Visual Impact

The glitter finish process involves uniformly dispersing one or several layers of glitter particles on the metal surface, providing the product with unique visual allure. This decorative technique can employ single-color glitter for a simple yet sophisticated shine or a mixture of multiple colors to create a rich, colorful effect. The density of the glitter particles can be adjusted—from finely sprinkled to create a subtle shimmer to broadly scattered for a more striking luminous effect. Additionally, there is an option to apply a transparent polyresin coating (AP) over the glitter layer. The poly coating not only smoothens the surface touch but also enhances the brightness of the glitter, making the reflections more prominent. Without the poly coating, the original matte texture of the glitter is preserved. Glitter is suitable for badges, keychains, fridge magnets, and trophies, frequently used in anime, cartoon, or sci-fi themed products.

Sandblasting

Uniform Roughness | Enhanced Adhesion | Surface Treatment

Sandblasting is a technique that involves high-speed sand particle jets to abrade the product surface, creating uniform roughness. This surface treatment not only enhances the adhesion of subsequent coatings but also removes impurities and oxidation layers. Sandblasting is widely used in pre-treatment of various metal surfaces, especially suitable for products that require painting or further chemical treatments, such as metal signs and components, improving product durability and aesthetics. During sandblasting, controlling the size of the sand particles and the pressure of the jets is crucial to achieving the desired surface roughness without damaging the metal's intrinsic structure.

Electrical Discharge Machining (EDM)

Fine Machining | Mold Making | Improved Precision

EDM, also known as spark machining, is a method that uses the thermal energy of electrical sparks to remove material, primarily used for the precision machining of metals. This technology allows for the creation of complex molds or microstructures on hard materials, often used for making fine molds and parts that are difficult to machine using traditional methods. The process ensures high precision and complexity in products, suitable for producing high-precision metal parts and intricate decorative details. EDM is particularly effective for handling hard alloys and super-hard materials, thus crucial for thicker and more complex (in terms of surface patterns or shapes) commemorative coins.

Polishing

Smooth Surface | Mirror Effect | Enhanced Aesthetics

Polishing is a process that involves using abrasive materials and polishing paste to treat metal surfaces at high speeds, achieving a mirror-like smooth finish. This not only enhances the visual appeal of the product but also helps improve its corrosion resistance. Polishing is commonly applied to products that need to showcase the natural luster of metal or a high-end texture, such as trophies, medals, and premium jewelry, making it a key step in enhancing the overall beauty and market competitiveness of products. Attention to detail and quality control is crucial during polishing to ensure a uniform, scratch-free high-standard finish.

Special Back Texture

Customized Design | Highlighting Personality

Special texture (customized as needed) offers a highly personalized back design option, allowing customers to customize unique back patterns or textures according to their specific needs and preferences. This design is suitable for clients who wish their products to stand out in the market, including but not limited to complex patterns, fine textures, or symbols with special meaning. Special textures can be achieved through laser etching, mechanical engraving, or other advanced surface treatment technologies to achieve precise and detailed effects. Applicable to luxury goods, limited edition memorabilia, or any metal products that need to highlight uniqueness and exclusivity. This highly customized service not only enhances the unique value of the product but also boosts brand recognition and customer satisfaction.

UV Transfer Sticker

Customizable | Vibrant Colors | Cost-Effective & Practical

The UV Transfer Sticker (also known as Metal Sticker or Crystal Label) is a cost-effective, customizable solution designed for promotional and commemorative products (with a specialized back design). Widely applied to metal items like badges, medals, and nameplates, it uses UV printing technology to create vivid colors and a 3D embossed effect. The sticker is waterproof, wear-resistant, heat-tolerant, and features strong adhesion for long-lasting use, even in harsh environments. For a premium finish, the Gold-Stamped UV Sticker offers a metallic sheen with a subtle raised effect. Its scratch-resistant and colorfast surface ensures lasting brightness and durability. Compared to laser engraving, UV Transfer Stickers allow for finer color details at a lower cost. Ideal for customized designs like serial numbers, logo changes, names, or minor adjustments, they add uniqueness to each product while offering flexible options to meet diverse market needs.

Perfect for bulk orders requiring batch-specific labels or limited-edition markings, these stickers eliminate the need for factory returns or complex processes. Just apply the sticker before release for quick and easy differentiation. Their cost-effectiveness, durability, and simplicity make them suitable for small-batch customizations or event-specific labels, streamlining inventory management and marketing.

Application is Simple: Peel off the sticker → Remove the desired design → Apply and press firmly → Slowly peel off the transparent film. No complex tools needed—just a quick and easy way to personalize products.

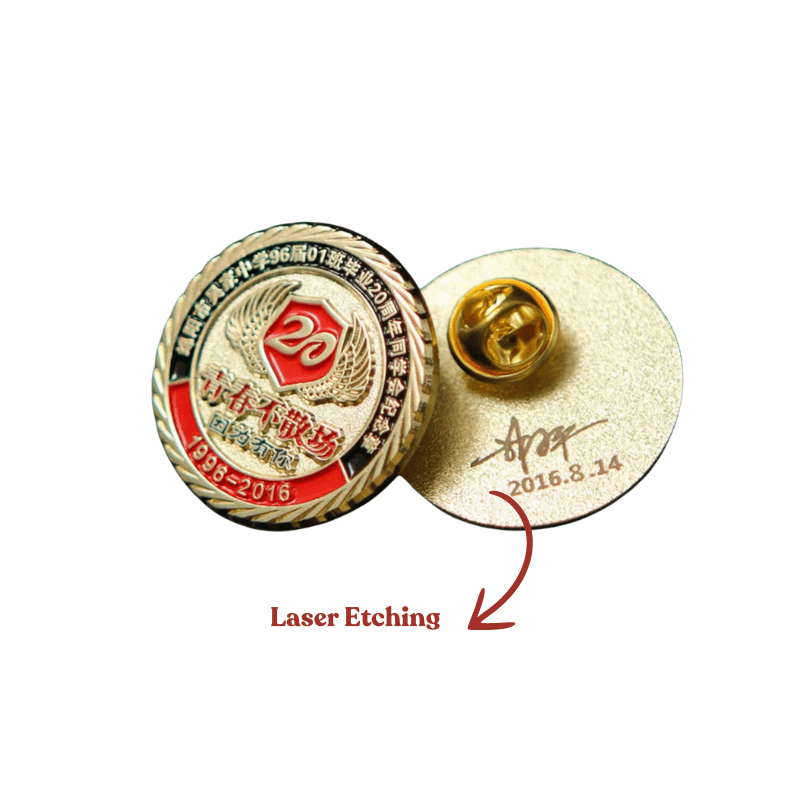

Laser Etching

High Precision Engraving | Sequential Numbering | Custom Content

Laser processing is an additional technique applied after product completion, using high-precision laser technology to engrave fine patterns or text on metal surfaces. This technology is suitable for metals as well as various other materials like PVC, especially for designs that require fine text or complex patterns. Laser processing allows for sequential numbering or custom content on the back of the product, providing subtle design variations that enhance the product's personalization and professionalism. The efficiency and versatility of this technology make it widely used in commercial promotion and personalized customization, such as engraving personal names, special dates, or unique patterns.

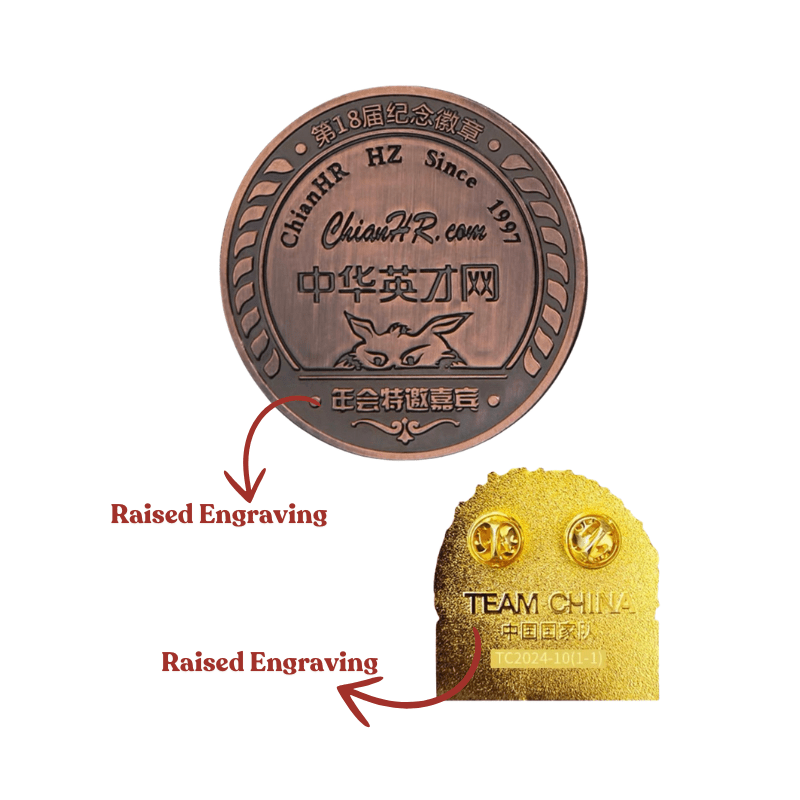

Raised Engraving (Above Metal Surface)

Strong Dimensionality | Rich Texture

Raised engraving is achieved by creating raised elements of text or patterns in the mold. During the metal forming process, these raised designs are transferred to the metal surface, forming three-dimensional patterns and text. This technique not only enhances the aesthetic appeal of the product but also provides a unique tactile experience. Raised engraving is particularly suitable for applications where the insignia or information needs to stand out prominently, such as corporate gifts and iconic medals. Due to its distinct three-dimensional effect, this technique excels in enhancing brand image and commemorative value.

Recessed Engraving (Below Metal Surface)

Precision Lasting | Rich Textures

Recessed engraving involves a process where design elements are engraved below the metal surface using molds. During the mold-making process, the design’s text or patterns form depressions in the metal surface. After the mold is completed, these indented patterns are precisely replicated on the metal product through die-casting or stamping, creating a uniform and richly textured visual effect. This method ensures a smooth overall tactile feel, especially suitable for metal products that require durability and uniform visual details, such as medals and high-end memorabilia. Additionally, products with an engraved indent design lie flatter and more stable when placed on surfaces, preventing wobbling. The precision of the engraved indent technique makes it an ideal choice for combining commemorative significance and practicality.

No Engraving on the Back

Clean and Pure | Versatility

Choosing no engraving on the back maintains the original state of the metal product without any text or patterns, showcasing the material's texture and color. This design is suitable for applications that focus on overall simplicity and pure aesthetic, such as high-end decorations and modern-style badges. It provides greater application possibilities and better visual integration. The option of no back engraving makes the product more versatile, maintaining its natural and high-quality appearance in various settings.

Electrical Discharge Machining (EDM)

Fine Sand Texture | Modern Technique

The fine sand effect by EDM (Electrical Discharge Machining) creates a delicate sand texture on the metal back using spark discharge technology. This unique surface texture not only enhances the tactile feel of the product but also gives it a distinct visual appeal. The fine sand effect is particularly suitable for high-end metal accessories and decorations that require increased friction and reduced fingerprint retention. This process is ideal for products that need improved aesthetics and enhanced slip resistance, such as high-end commercial signs and custom decorations.

Fabric Texture

Textured Presentation | Enhanced Grip

The fabric texture back design is created through a special process that imitates the texture of fabric on the metal back. This design not only enhances the aesthetic appeal of the product but also improves the tactile feel, making it easier to grasp and carry. Fabric texture treatment is widely used on metal products that require added slip resistance and a sense of visual depth, such as metal signs and nameplates. It provides a unique tactile experience while achieving a perfect balance between functionality and aesthetics.

Glossy and Smooth

Sleek Smoothness | Simple Elegance

The polishing process involves using abrasive materials and polishing paste to treat metal surfaces at high speeds, achieving a mirror-like smooth effect. This not only enhances the product’s visual appeal but also helps improve its corrosion resistance. Polishing is commonly applied to products that need to display the natural luster of metal or a high-end texture, such as trophies, medals, and premium jewelry. It is a key step in enhancing the overall beauty and market competitiveness of products. During polishing, attention to detail and quality control is crucial to ensure a uniform and scratch-free high-standard finish.