Blister packaging is a cost-effective packaging option, especially suitable for mass-produced small items needing individual packaging for retail or other purposes, such as badges, keychains, and small metal decorative items and gifts. This type of packaging is made of plastic material, shaped by thermoforming technology, which heats the plastic sheet until soft, then molds it around the product using a form, and cools it to solidify, accurately encircling the product contour to ensure stability and protection during transportation and display. Blister packaging is not only economical but also lightweight and transparent, greatly facilitating consumer's visual inspection before purchase. Additionally, the packaging can be customized in shape, size, and printed patterns to enhance brand recognition.

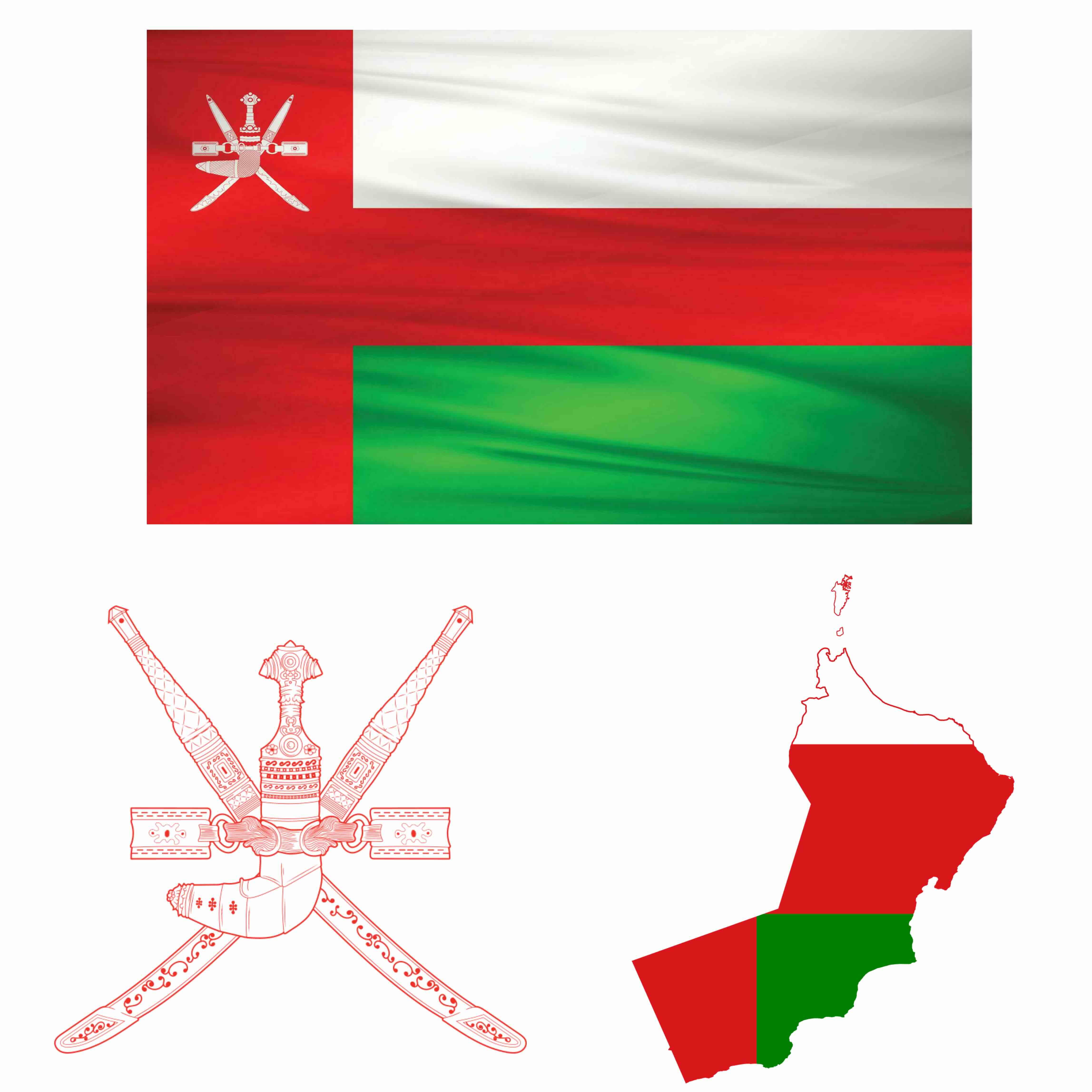

Cultural Symbols of the Sultanate of Oman: Historical Context, National Emblem, National Day, and an Overview of the ASNY Gift Collection

I. National Profile of Oman: A Symbolic System of Historical Continuity and Cultural Stability The Sultanate of Oman is located on the southeastern coast of the Arabian Peninsula, covering about 309,500 square kilometers. It is one of the region’s countries with the most uninterrupted historical continuity. Since 1744, the Al Busaidi Dynasty has provided a stable political framework, shaping a long-term structure defined by political stability and strong cultural traditions. Oman’s population is approximately 5.28 million (2024), with foreign residents accounting for about 43%. The capital, Muscat, has around 1.4 million people and is the nation’s administrative, economic, and cultural

2025/12/02

145 Views