ASNY Craft Factory specializes in the production of photo etched badges using precise etching techniques. This process involves transferring designs from photographic negatives onto metal surfaces, followed by etching out intricate patterns in an acidic environment. This technique allows for the creation of extremely fine and complex graphics on the metal surface, where each detail is vividly brought to life, offering a unique visual impact. Photo etched badges are often used for high-end badges that require the display of fine artistic details, such as for art exhibitions, special events, or as premium gifts. These badges typically serve as collectible items and are an ideal choice for high-end brands to showcase their uniqueness and professionalism.

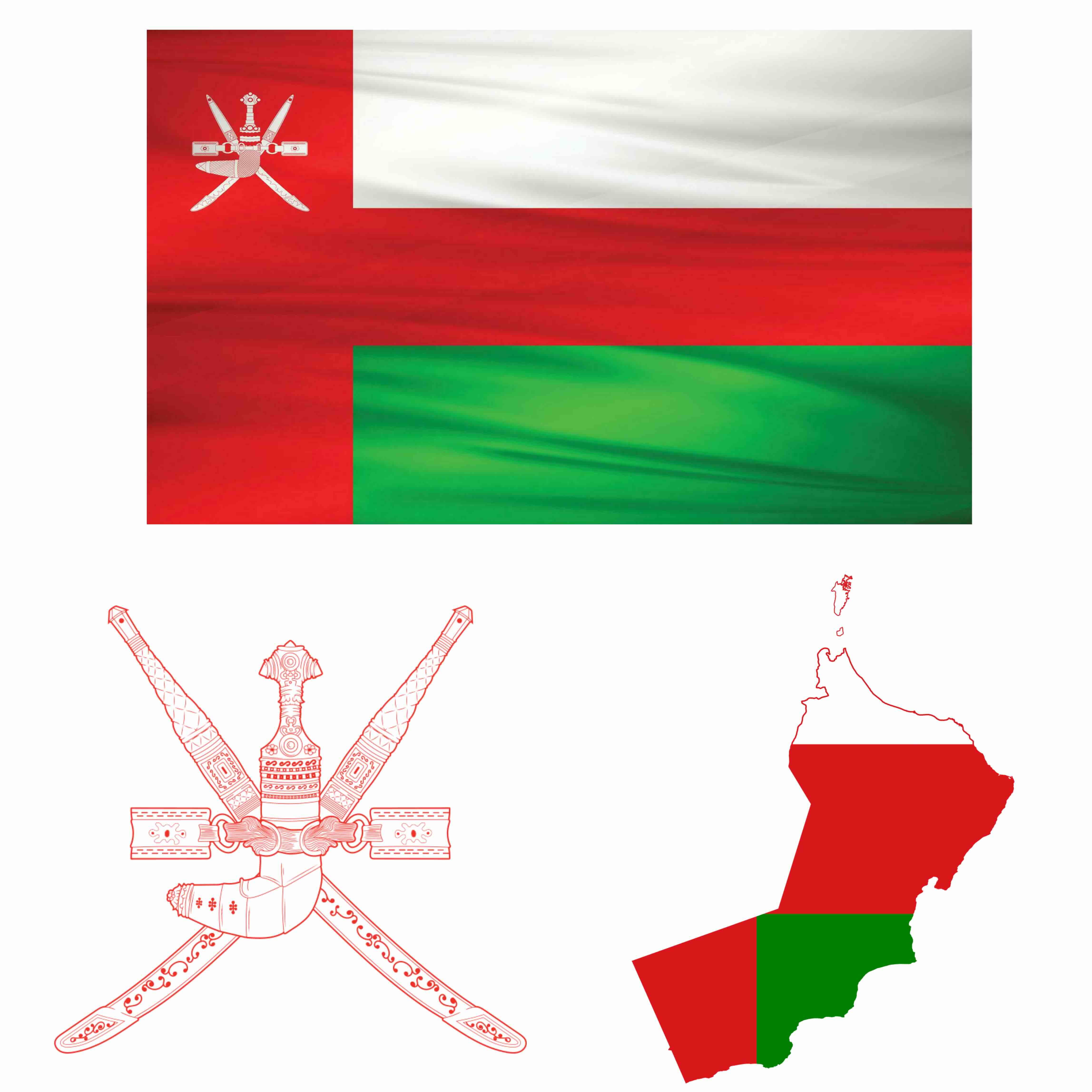

Cultural Symbols of the Sultanate of Oman: Historical Context, National Emblem, National Day, and an Overview of the ASNY Gift Collection

I. National Profile of Oman: A Symbolic System of Historical Continuity and Cultural Stability The Sultanate of Oman is located on the southeastern coast of the Arabian Peninsula, covering about 309,500 square kilometers. It is one of the region’s countries with the most uninterrupted historical continuity. Since 1744, the Al Busaidi Dynasty has provided a stable political framework, shaping a long-term structure defined by political stability and strong cultural traditions. Oman’s population is approximately 5.28 million (2024), with foreign residents accounting for about 43%. The capital, Muscat, has around 1.4 million people and is the nation’s administrative, economic, and cultural

2025/12/02

143 Views