ASNY Craft Factory offers rivets specifically designed for securing and decorating various badges and plaques. Made from corrosion-resistant metal materials, these rivets ensure stable fixation in all environments. Designed for both aesthetics and functionality, rivets are widely used in situations requiring permanent attachment, such as public signage, commercial billboards, and various promotional signs. ASNY’s rivets are also used in exquisite art installations and complex decorative crafts, their reliable fixation power and elegant appearance making them a preferred choice for artisans and designers. Additionally, rivets are used in assembling medals and trophies, ensuring these important items remain intact during long-term display or use.

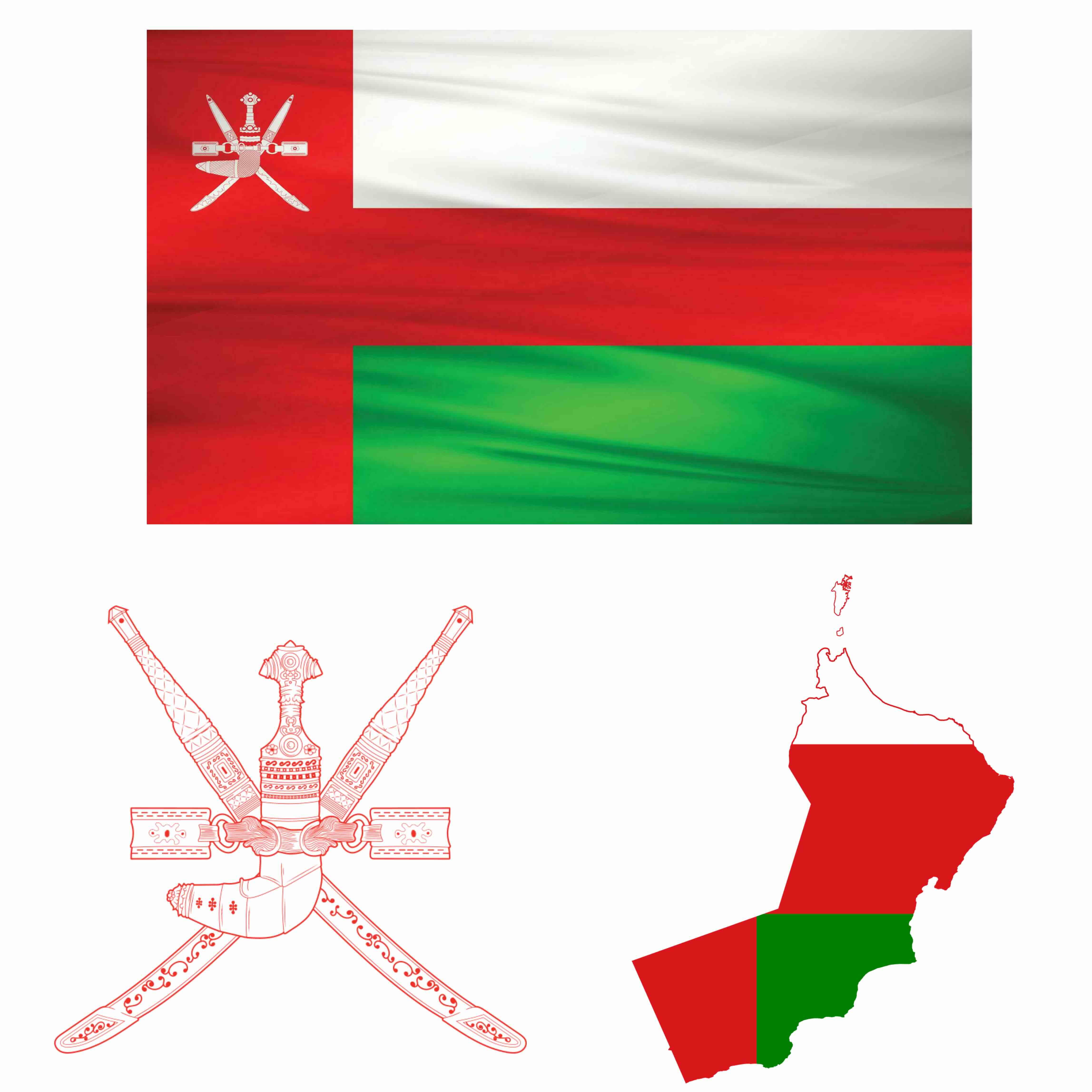

Cultural Symbols of the Sultanate of Oman: Historical Context, National Emblem, National Day, and an Overview of the ASNY Gift Collection

I. National Profile of Oman: A Symbolic System of Historical Continuity and Cultural Stability The Sultanate of Oman is located on the southeastern coast of the Arabian Peninsula, covering about 309,500 square kilometers. It is one of the region’s countries with the most uninterrupted historical continuity. Since 1744, the Al Busaidi Dynasty has provided a stable political framework, shaping a long-term structure defined by political stability and strong cultural traditions. Oman’s population is approximately 5.28 million (2024), with foreign residents accounting for about 43%. The capital, Muscat, has around 1.4 million people and is the nation’s administrative, economic, and cultural

2025/12/02

141 Views