ASNY Craft Factory’s screws and nuts are designed for products that require extra fixing strength and a vintage aesthetic. These accessories are commonly used in high-end products such as 3D vintage badges and automotive emblems. Their design not only ensures a tight connection between components but also adds a mechanical and historical feel. Screws and nuts require rotation for tightening, providing a reliable and reversible method of attachment, suitable for applications that may need frequent disassembly or adjustment. In the customization of automotive emblems, screws and nuts not only ensure the firm installation of the emblem but also accentuate the brand’s high quality and precision craftsmanship through their metallic texture and exquisite manufacturing.

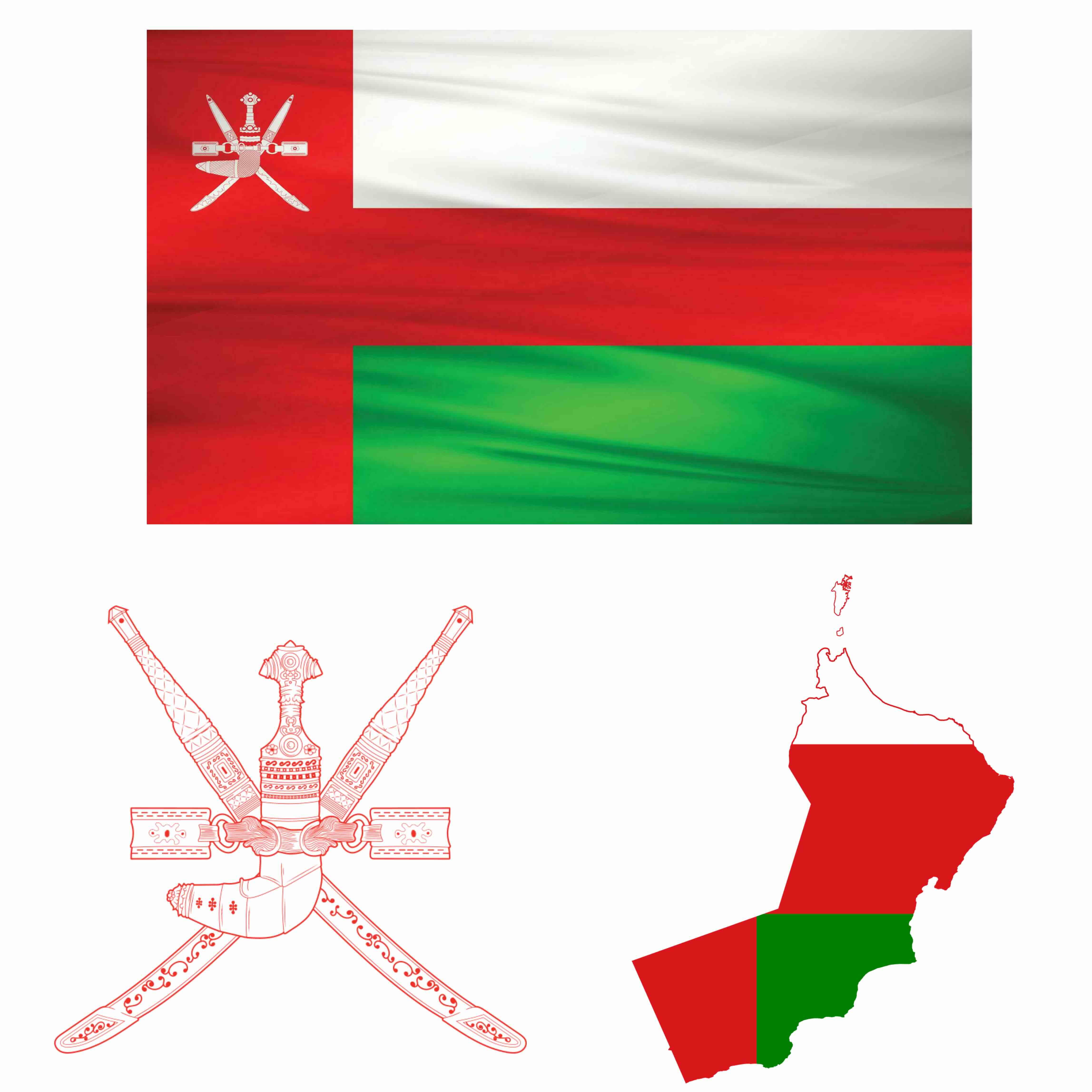

Cultural Symbols of the Sultanate of Oman: Historical Context, National Emblem, National Day, and an Overview of the ASNY Gift Collection

I. National Profile of Oman: A Symbolic System of Historical Continuity and Cultural Stability The Sultanate of Oman is located on the southeastern coast of the Arabian Peninsula, covering about 309,500 square kilometers. It is one of the region’s countries with the most uninterrupted historical continuity. Since 1744, the Al Busaidi Dynasty has provided a stable political framework, shaping a long-term structure defined by political stability and strong cultural traditions. Oman’s population is approximately 5.28 million (2024), with foreign residents accounting for about 43%. The capital, Muscat, has around 1.4 million people and is the nation’s administrative, economic, and cultural

2025/12/02

141 Views