The embossed soft enamel badges produced by ASNY Craft Factory can be enhanced with an additional layer of poly resin coating. This special coating effectively protects the badge surface from scratches and environmental factors. The poly resin layer increases the gloss and visual impact of the badge while enhancing its durability and wear resistance. These high-grade badges are particularly suitable for situations requiring long-term display or frequent use, such as outdoor activities, employee identification tools, and as enduring displays for companies or organizations. This process not only enhances the functional aspects of the badge but also significantly improves its aesthetic and protective qualities.

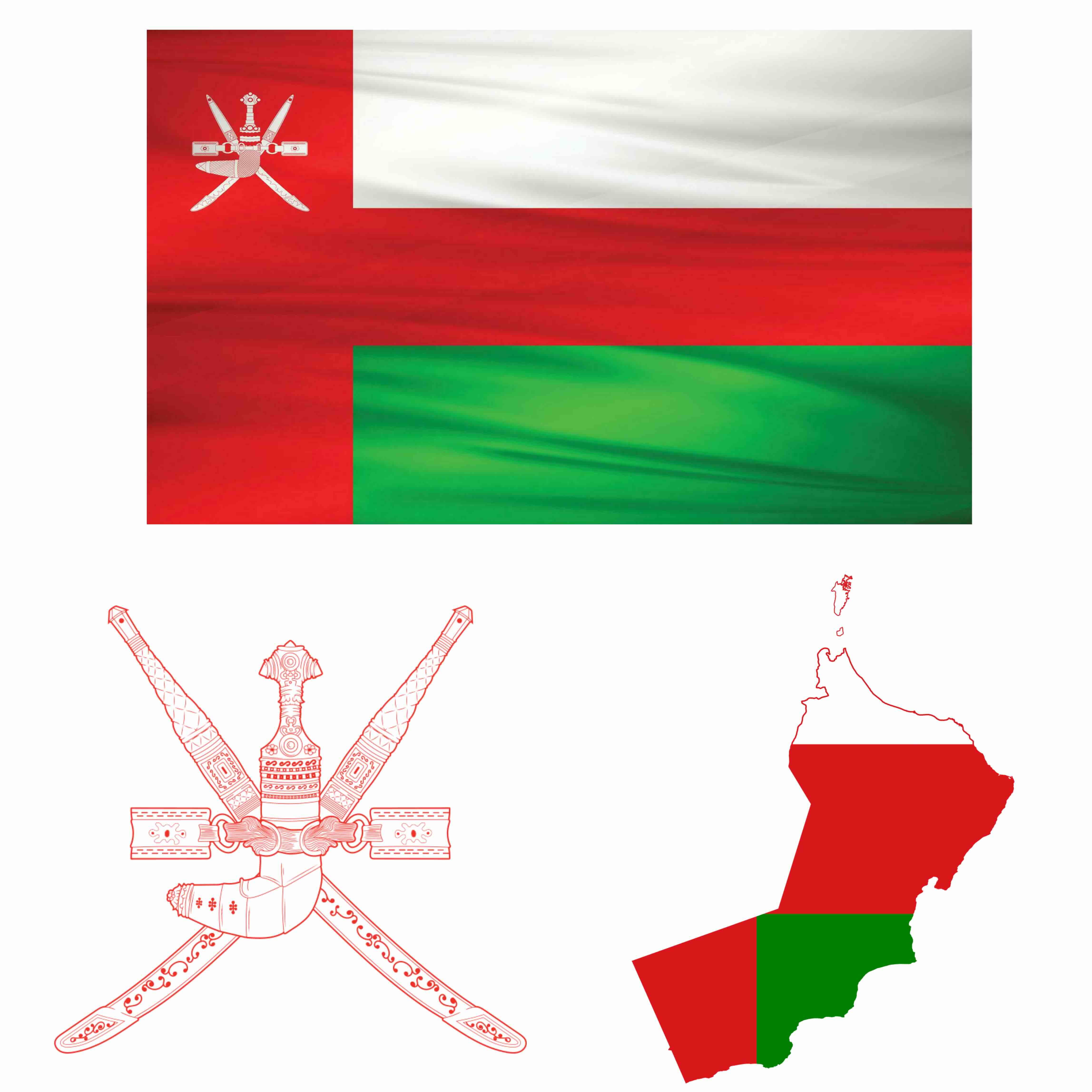

Cultural Symbols of the Sultanate of Oman: Historical Context, National Emblem, National Day, and an Overview of the ASNY Gift Collection

I. National Profile of Oman: A Symbolic System of Historical Continuity and Cultural Stability The Sultanate of Oman is located on the southeastern coast of the Arabian Peninsula, covering about 309,500 square kilometers. It is one of the region’s countries with the most uninterrupted historical continuity. Since 1744, the Al Busaidi Dynasty has provided a stable political framework, shaping a long-term structure defined by political stability and strong cultural traditions. Oman’s population is approximately 5.28 million (2024), with foreign residents accounting for about 43%. The capital, Muscat, has around 1.4 million people and is the nation’s administrative, economic, and cultural

2025/12/02

151 Views