Zipper poly bags are designed with high adaptability and functionality. They can be transparent or opaque and are available in sizes ranging from very small to sufficiently large, suitable for individual or bulk packaging of items. These bags typically feature a one-time sealing mechanism that ensures product freshness and integrity until the initial opening. After tearing, the resealable design at the bottom allows the bags to be reused, providing a long-term storage solution. Customization options include printing a company logo, usage instructions, and barcodes, enhancing brand impact and user convenience, making them a preferred packaging solution in promotional and retail environments.

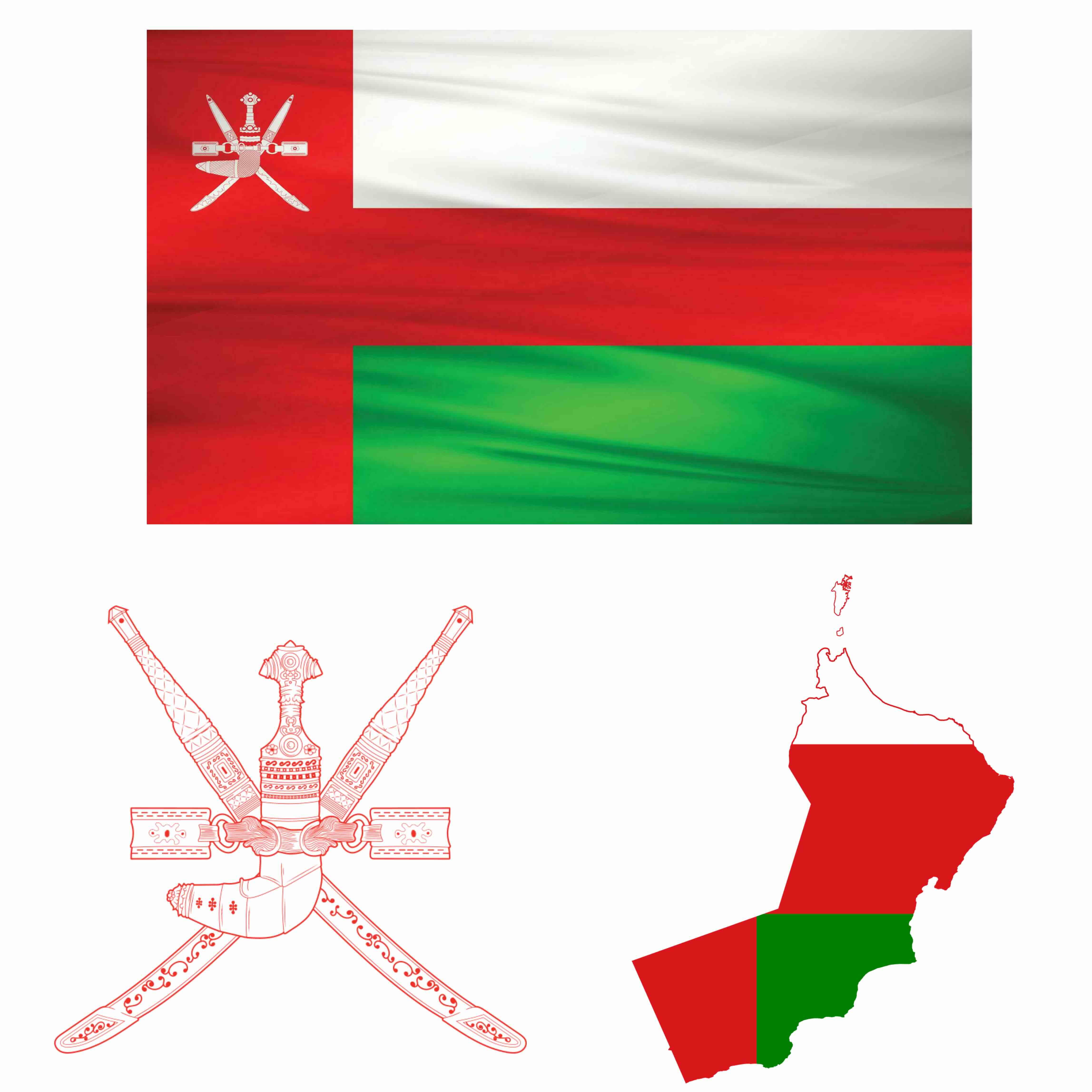

Cultural Symbols of the Sultanate of Oman: Historical Context, National Emblem, National Day, and an Overview of the ASNY Gift Collection

I. National Profile of Oman: A Symbolic System of Historical Continuity and Cultural Stability The Sultanate of Oman is located on the southeastern coast of the Arabian Peninsula, covering about 309,500 square kilometers. It is one of the region’s countries with the most uninterrupted historical continuity. Since 1744, the Al Busaidi Dynasty has provided a stable political framework, shaping a long-term structure defined by political stability and strong cultural traditions. Oman’s population is approximately 5.28 million (2024), with foreign residents accounting for about 43%. The capital, Muscat, has around 1.4 million people and is the nation’s administrative, economic, and cultural

2025/12/02

151 Views